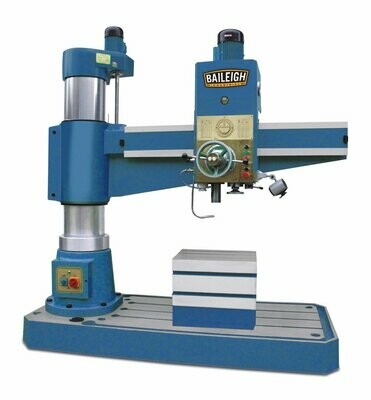

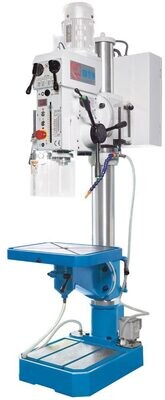

Knuth KSR 40 Advance Rapid Radial Press ( Part No. 162363 ) Linear guides for easy handling and stability

Knuth KSR 40 Advance Rapid Radial Press

( Part No. 162363 )

Linear guides for easy handling and stability

Ex stock availability. 4 weeks. Subject to no prior sales

Highlights

- Knuth KSR 40 Advance Rapid Radial Drill Press

- The high-speed radial drilling machines of the KSR series are designed according to the "tool to workpiece" machining principle and are often used in maintenance and in tool and steel construction. The design offers unique flexibility and plenty of work space for larger workpieces, so that one side of the workpiece can be completely machined without repositioning. The machine frame offers clamping surfaces for clamping devices and workpieces on three sides. The quill feed can be varied in four stages using a gearbox and a manual, mechanically adjustable depth stop.

- Unique operating concept

- 3 workstations

- Quill feed with gear

- Digital depth display

- tapping device

- Extensive accessories

Detail

- Powerful machine suitable for drilling, tapping, countersinking and boring

- Optimum clamping and machining options thanks to large travel distances and a large number of different machining stations

- Extremely stable construction ensures high accuracy and reliability

- Quick and precise positioning of the tool: the hydraulic clamp is released at the push of a button - the head can be swiveled forwards, backwards and horizontally with ease

- Drilling head can be motorized up and down

- The height can be adjusted without changing the drilling position

- Enables flexible processing of large workpieces

- ± 90 degree pivoting drilling head

- Automatic feed with depth switch

- Thick-walled column and powerful dimensioning of all components ensure high accuracy

- Digital drilling depth display

- Optimum ease of use thanks to infinitely variable spindle speed with digital display and digital drilling depth display

Technical Details

| WORKSPACE | |

|---|---|

| drilling performance | 40mm |

| table mounting surface | 1200mm x 505mm |

| T-slots, number | 3 pieces |

| T-slots, width | 18mm |

| Tapping performance, steel | M30 |

| unloading | 950mm |

| Distance spindle nose - table surface | 780mm |

| quill stroke | 200mm |

| column diameter | 220mm |

| Swivel range head | ± 90 degrees |

| column lift | 380mm |

| TRAVERSE PATHS | |

|---|---|

| Travel upper beam | 590mm |

| MAIN SPINDLE | |

|---|---|

| spindle mount | 4 MK |

| Spindle speed (infinitely variable) | 50 rpm - 2000 rpm |

| FEED | |

|---|---|

| feeds | 0.08mm/rev - 0.5mm/rev |

| Feed Levels | 6 |

| DRIVE POWER | |

|---|---|

| Main drive engine power | 2.2kW |

| Motor power height adjustment | 1.5kW |

| Engine power coolant pump | 0.37kW |

| MASS AND WEIGHT | |

|---|---|

| Dimensions (length x width x height) | 1.72m x 1.2m x 2.25m |

| Weight | 2740kg |

Standard Equipment

Digital speed display

Additional clamping surfaces on the side and rear

Cube table Swiveling

horizontal table

Digital drilling depth display

Work lamp

Coolant device

Thread cutting device Drill

chuck with plug -in pin

Reducing

sleeves Operating tools Operating

instructions

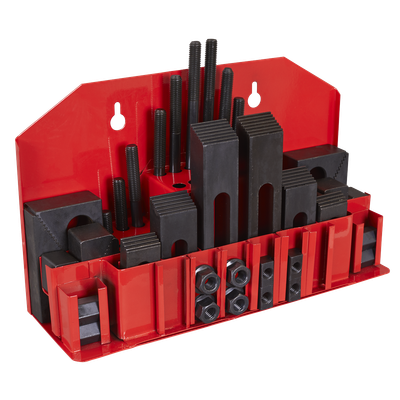

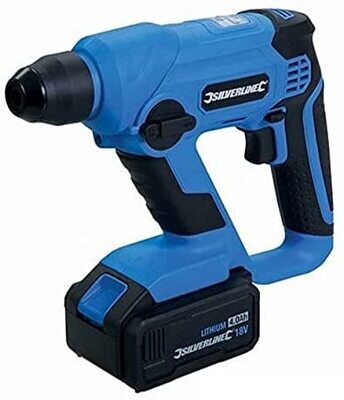

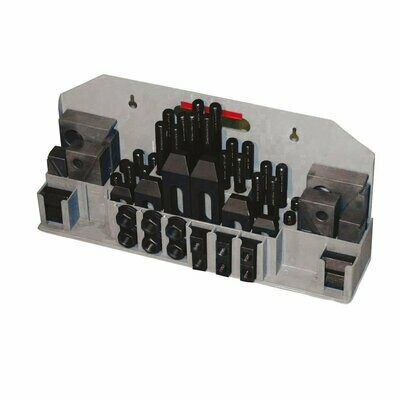

Optional Equipment

Wide range of optional equipment available for this machine as follows

Please contact us via email for price details of any options of interest.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.