Knuth Servo Turn 500/1000 Universal Lathe( Part No. 300831 ) Conventional turning with the precision and dynamics of modern CNC machines

Knuth Servo Turn 500/1000 Universal Lathe

( Part No.300831 )

Conventional turning with the precision and dynamics of modern CNC machines

Ex Stock Availability, 4 weeks, Subject to No Prior Sales.

Highlights

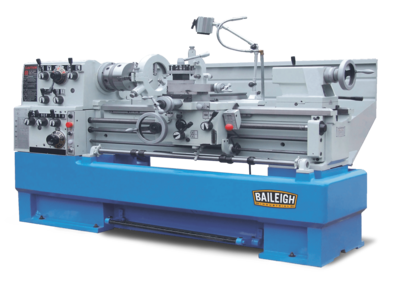

Knuth Servo Turn 500 / 1000 Universal Lathe

The Servoturn series of universal lathes combine the latest feed technology with classic mechanical engineering. In contrast to conventional lathes, this series has ball screw drives and electronic handwheels in all axes. High-torque servomotors convert every feed movement with the dynamics of modern CNC machines. Feed and thread pitches can be selected electronically without change gears and gears. Rapid traverses in all axes reduce non-productive times and electronic stops offer high repeatability.

- Servo feed system

- Ball screws in all axes

- Electronic handwheels

- Position indicator with V-constant function

- Quick change tool holder

Detail

- The combination of a machine base that has been tried and tested many times over and state-of-the-art feed technology makes switching to servo-conventional lathes even more attractive and economical

- Intuitive operation, as known from conventional machines, only much better:

- Feed and thread pitch can be selected via rotary switch - simply brilliant

- Stops can be set electronically at the push of a button

- Feeds are infinitely adjustable via override potentiometer - finally also with conventional turning

- Operation via electronic handwheels in the µ range - in feel and position as with a conventional machine

- The axes are moved by high-quality servo drives that convert your hand wheel movements with the precision and dynamics of modern CNC machines

- Infinitely variable speed control and constant cutting speed of the main spindle

- V-constant - the spindle speed is automatically adapted to the changing workpiece diameter during face turning - the almost constant cutting speed on the turning tool cutting edge enables a surface quality that is comparable to the turning results of CNC lathes

- Machine frame

- The heavily ribbed machine frame with its wide, hardened prism bed guides is designed for heavy-duty machining

- The design of the headstock and the main spindle is aimed at stability and damping with a balanced temperature balance

- This entire series is also characterized by large spindle bores

- The standard quick-change tool holder makes working with the machine flexible and productive

- Feed

- Ball screw drives in the X and Z axes offer the decisively smaller backlash error, which is reflected in significantly increased precision

- Furnishing

- The machine is equipped with a central lubrication unit for low-maintenance operation

- The solid tailstock impresses with its easy handling and high clamping force

- Incl. 3-axis position indicator with integrated spindle speed indicator, fully assembled

- 3 Axis Position Indicator

- Higher work accuracy

- Lower error rate

- Greater production security

- Significant time savings

- productivity increase

- Optimal readable display

- User-friendly functions

- Clearly arranged keyboard

- Resolution 0.01 / 0.005mm

- coordinate value specification

- Retaining the axis position when the display is switched off

- Storage for 10 tools

- Radius / diameter switching

Technical Details

| WORKSPACE | |

|---|---|

| turning diameter over bed | 500mm |

| Circulation Ø over support | 300mm |

| bed width | 400mm |

| peak width | 950mm |

| TRAVERSE PATHS | |

|---|---|

| X axis travel | 250mm |

| Z axis travel | 880mm |

| Z1 axis travel | 100mm |

| MAIN SPINDLE | |

|---|---|

| spindle mount | A2-8 |

| spindle speed | 30 rpm - 1600 rpm |

| lathe chuck diameter | 250mm |

| spindle bore | 86mm |

| RAPID TRAVERSE | |

|---|---|

| Rapid X axis | 4m/min |

| Rapid Z axis | 4m/min |

| FEED | |

|---|---|

| Feed X axis | 0.01mm/rev - 2mm/rev |

| Feed Z axis | 0.01mm/rev - 2mm/rev |

| THREADING | |

|---|---|

| Threading Whitworth | 48-4 TPI |

| Threading, Metric | 0.35-14mm |

| TAILSTOCK | |

|---|---|

| tailstock cone | 5 MK |

| tailstock quill stroke | 150mm |

| tailstock quill diameter | 75mm |

| DRIVE POWER | |

|---|---|

| Main drive engine power | 6kW - 9kW |

| Motor power X axis | 1.5kW |

| Motor power Z axis | 2.3kW |

| supply voltage | 400v |

| MASS AND WEIGHT | |

|---|---|

| Dimensions (length x width x height) | 3.2m x 1.28m x 1.65m |

| Weight | 2850kg |

Standard Equipment

3-axis position indicator 3

-jaw chuck Ø 250 mm

electronic handwheels

quick-change tool holder

fixed steady rest moving

steady

coolant system

splash protection wall

support shield

work

lamp

operating tools operating instructions

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

The certificate holder's Management System corresponds to standard ISO 9001:2015.