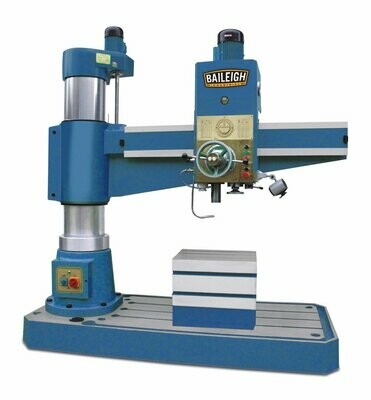

Knuth R 60 VT Radial Drill Press ( Part No. 101656 ) The first servo conventional radial drill press

Knuth R 60 VT Radial Drill Press

( Part No. 101656)

The first servo conventional radial drill press

Ex Stock Availability. 4 weeks . Subject to No Prior Sales.

Highlights

R 60 VT Radial Drill Press

The R 60 VT model belongs to the latest generation of the widely used radial drilling machines. The unique operating concept simplifies processing and supports the operator in selecting the operating parameters. This model enables precise drilling, countersinking and tapping and is the ideal solution for one-off and small series production. This radial drilling machine is often used in maintenance, tool and steel construction.

- Unique operating concept

- Extended control of machine functions

- Quill feed with servo motor

- Massive construction ensures high stability

Detail

- The base, column, boom and gear head are made of high-quality cast iron

- The main design features are the large dimensioned column and the particularly torsion-resistant boom

- The height of the boom is adjusted via a powerful motor drive and lifting spindle

- The boom lifting gear runs in an oil bath and works reliably and with little wear

- The swivel and traversing axes are characterized by their exceptional ease of movement and relieve the operator in everyday production

- A central lubrication reliably supplies the column with lubricant

Electronically controlled servo quill feed with large touchscreen display

- The drilling depth is set electronically and the input value is checked by the system

- The unit of measurement for the entries and displays can be selected between mm and inch

- The powerful coolant device is activated on the touchscreen and then switched on or off depending on the main spindle

- The machine has 2 gear stages in which the speed can be continuously adjusted and displayed on the monitor

- A servomotor continuously controls the quill feed - when the feed has reached the preselected drilling depth, the quill automatically returns to the starting position

- Thread cutting, on the other hand, is purely manual, with the operator changing the direction of rotation of the quill once the thread depth has been reached

- The operator can position the jib in height by touching the corresponding icon. The system automatically releases and fixes the hydraulic clamp, switches on the hoist motor and takes the set end stops into account

- Drill head and column can be clamped or released together or separately

- The boom can be moved in height without losing the alignment of the spindle to the bore

- The control software also offers recommendations for speed and feed, depending on the desired drill size

- Various alarm displays warn the operator of operating errors or show the operating status

Technical Details

| WORKSPACE | |

|---|---|

| drilling performance | 60mm |

| Tapping performance, cast iron | M50 |

| Tapping performance, steel | M45 |

| drilling depth (max.) | 315mm |

| unloading | 350mm - 1600mm |

| Distance spindle nose - table surface | 350mm - 1250mm |

| Drill head travel (horizontal) | 1250mm |

| MAIN SPINDLE | |

|---|---|

| RPM range levels | 2 |

| speed range | 38 rpm - 2000 rpm |

| spindle mount | MK 5 |

| FEED | |

|---|---|

| feeds | 0mm/min - 300mm/min |

| DRIVE POWER | |

|---|---|

| Main drive engine power | 4kW |

| lift motor | 1.5kW |

| MASS AND WEIGHT | |

|---|---|

| Dimensions (length x width x height) | 2.49m x 1.05m x 2.78m |

| Weight | 3800kg |

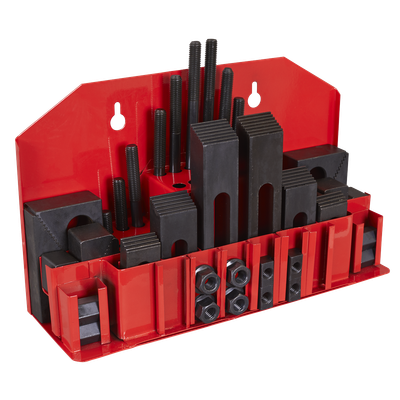

Standard Equipment

Touchscreen control panel

Coolant

system Cube table

LED work lamp

Operating instructions

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.