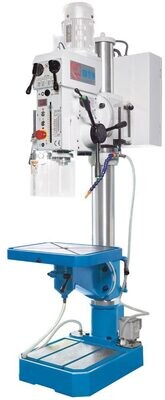

Knuth SBF 40 TV 1000 Column Drill Press With Milling Function. ( Part No. 101573) Universal Machine for milling and drilling.

Knuth SBF 40 TV 1000 Column Drill Press With Milling Function.

( Part No. 101573)

Availability.Currently 4 weeks to site from receipt of order.Subject to no prior sales.

Highlights

- Knuth SBF 40 TV 1000 Column Drill Press With Milling Function.

The SBF is a drilling and milling machine in the best way. It is ideal as a drill with a powerful drive and a wide speed range. You can also use this machine to mill steel and non-ferrous metals. This makes the SBF 40 a drill with additional benefits at an unbeatable price.

- Extended table length with auto feed on X-axis

- Automatic drilling feed with depth display

- Gearbox milling head for powerful machining

- Swiveling head for wide range of applications

Detail

- Drilling and Milling - a true added value for a low price

- Large compound sliding table with automatic infinitely variable feed on X-axis for coordinate drilling and light milling work

- Quiet operation with oil-bath lubricated gears for long tool life and durability

- The milling machine's high-quality spindle bearing can withstand higher loads for the long term

- Manual drill feed can be switched to high-precision feed via a hand-wheel

- Controllable automatic feed with 3 gear steps

- Adjustable height of gear head and table

- Table guides are adjustable with high precision via taper gibs

- Gear head swivels to both sides

- Cutter mounts are secured by an M16 drawbar

- Tapping feature

- Integrated coolant system

Technical Details

| WORKING AREA | |

|---|---|

| Table set up area | 730 mm x 210 mm |

| Tapping capacity, steel | (ST 37) M16 |

| Throat | 278 mm |

| Spindle nose-to-table surface distance | 600 mm |

| Quill stroke | 120 mm |

| Column diameter | 115 mm |

| Spindle nose-to-foot distance | 1180 mm |

| Table load capacity (max.) | 100 kg |

| Number of table T-slots | 3 positions |

| T-slot table (width x spacing) | 14 mm x 63 mm |

| T-slot foot (qty) | 2 positions |

| T-slot foot (width x spacing) | 14 mm x 200 mm |

| Drilling capacity in steel / ST37 | 40 mm |

| Head swivel range | ± 45° |

| TRAVELS | |

|---|---|

| Travel X-axis | 500 mm |

| Travel Y-axis | 190 mm |

| Z1 / Z2 axis travel | 530 mm |

| HEADSTOCK | |

|---|---|

| Speed range-stages | 12 |

| Speed range | 75 1/min - 3200 1/min |

| Spindle mount | 4 MT |

| RAPID FEED | |

|---|---|

| Rapid feed | 600 mm/min |

| FEED | |

|---|---|

| Work feed | 0 mm/min - 420 mm/min |

| DRIVE CAPACITY | |

|---|---|

| Main motor rating | 1,5 / 1,1 kW |

| Motor rating coolant pump | 0,04 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 0,83 m x 0,76 m x 1,85 m |

| Weight | 390 kg |

Standard Equipment

- tapping unit

table feed TV 1000

draw bar

drill chuck

tool-holder bits

coolant system

operator manual

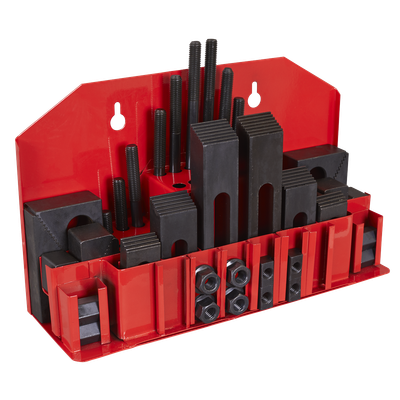

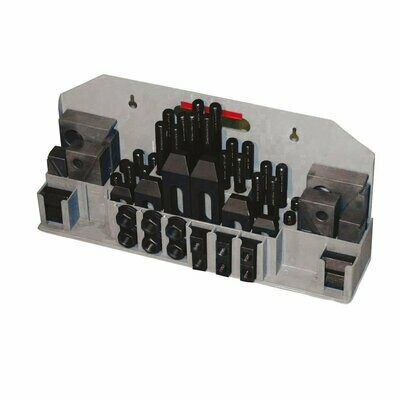

Optional Equipment

Wide range of tooling options available

Contact us via Email for price details of any tooling options of interest.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.