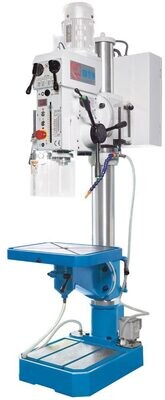

Knuth Mark Super S Drilling & Milling Machine ( Part No. 301498) Compact design and versatility. Still a bestseller with a 15 year production run track record.

Knuth Mark Super S Drilling & Milling Machine

( Part No. 301498)

Compact design and versatility. Still a bestseller with a 15 year production run track record.

Availability. Currently 4 weeks to site from receipt of order. Subject to no prior sales.

Highlights

Knuth Mark Super S Drilling & Milling Machine

The models of the Mark Super series are drilling and milling machines in the best way. They are ideal as a compact drill with a powerful drive and a wide speed range. But these machines also cut a fine figure when milling steel and non-ferrous metals. They are therefore widespread in workshops and maintenance departments for single piece machining, small series production or training departments. Thanks to their compact design and versatility, they are still a bestseller even after 15 years.

- Extended table length with auto feed on X-axis

- Automatic drilling feed with depth display

- Gearbox milling head for powerful machining

- Swiveling head for wide range of applications

- Stepless spindle speed with digital display (SV model only)

Detail

- More power and variable speed control for a wider range of applications

- Motorized cutter head movement and hand-wheel for exact positioning of head

- Hand-wheel for quill micro-feed

- Digital depth indicator for quill travel

- Tapping unit with adjustable rotation reversal for thread cutting

- Hardened gear racks and shafts for quiet operation and long life

- Rigid base with storage room is included

- Infinitely variable feed on X-axis is included

- More accuracy

- Lower error rate

- Increased productivity

- Resulting in valuable time savings

- For increased productivity

- Easy to read display

- Operator-specific features

- Convenient keyboard layout

- Resolution: 0.01/ 0.005 mm

- Default coordinates

- Axis position is maintained when display is turned off

- Hole circle pattern calculation

- Calculator function

- Storage for 10 tools

- Radius / diameter toggle

- Mm/inch conversion

- Easy expansion and maintenance-free operation

- Two gear steps and premium frequency control technology ensure high torque across the entire speed range for powerful machining

- The selected spindle speed is displayed directly on the control panel

Technical Details

| WORKING AREA | |

|---|---|

| Table dimensions | 800 mm x 240 mm |

| Number of table T-slots | 3 positions |

| T-slot table (width x spacing) | 14 mm x 80 mm |

| Drilling capacity in steel | 32 mm |

| Shaft milling | 32 mm |

| Head elevation | 350 mm |

| TRAVELS | |

|---|---|

| Travel Y-axis | 190 mm |

| Travel X-axis manual / autom. | 560 / 480 mm |

| VERTICAL MILLING HEAD | |

|---|---|

| Throat | 258 mm |

| Spindle mount | MT 4 |

| Quill stroke | 120 mm |

| Head swivel range | ± 45° |

| Quill diameter | 75 mm |

| Spindle nose-to-table distance | 460 mm |

| Speed | (12) 75-3200 1/min |

| DRIVE CAPACITY | |

|---|---|

| Main motor rating | 1,5 / 1,1 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,25 m x 0,95 m x 2,13 m |

| Weight | 380 kg |

Standard Equipment

- automatic quill feed

3-axis position indicator

base

table feed TV 1000

drill chuck 13 mm

tool-holder bits

operator manual

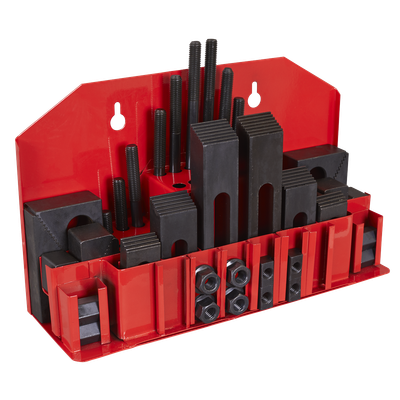

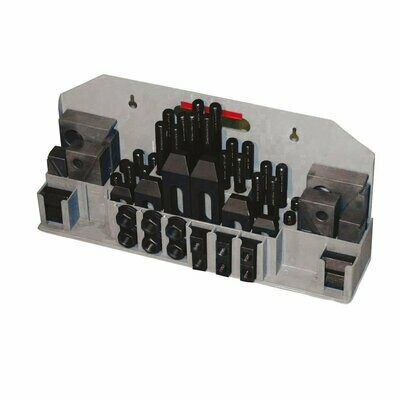

Optional Equipment

Wide range of tooling options available

Contact us via Email for price details of any tooling options of interest.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.