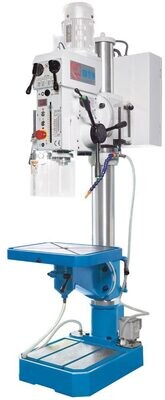

Knuth UWF 1.1 Universal Milling Machine ( Part No. 362693 ) Solid design, rigid construction for vertical and horizontal machining

Knuth UWF 1.1 Universal Milling Machine

( Part No. 362693)

Solid design, rigid construction for vertical and horizontal machining

Availability. Currently 4 weeks from receipt of order. Subject to no prior sales.

Highlights

Knuth UWF 1.1 Universal Milling Machine

The milling machine is equipped with a large clamping table and a swiveling universal milling head that can be swiveled in two planes and also positioned horizontally. The UWF series thus almost covers the area of application of a universal milling machine. An automatic feed that can be switched via a gearbox drives the X- and Y-axes. The Z-axis can be traversed in rapid traverse. Dovetail guides in all axes can be precisely adjusted. With its extensive equipment, the UWF 1.1 is ideal for individual production, repair and training workshops.

- Universal cutter head swivels on 2 levels

- Horizontal milling spindle with its own drive

- Feed on X-axis and Y-axis

- Extensive standard equipment

Details

- Heavy machine frame with wide, adjustable dovetail guides in all axes

- Rigid universal cutter head, can be moved to virtually any spatial angle on two levels

- Automatic table feed on X- and Y-axes, including rapid feed

- Motorized height adjustment in Z direction

- Higher work accuracy

- Lower error rate

- Greater production security

- Significant time savings

- productivity increase

- Optimal readable display

- User-friendly functions

- Clearly arranged keyboard

- Resolution 0.01 / 0.005mm

- coordinate value specification

- Retaining the axis position when the display is switched off

- Bolt circle pattern calculation

- calculator function

- Storage for 10 tools

- Radius / diameter switching

- Conversion mm/inch

- Easy attachment and maintenance-free operation

3-axis position indicator

Technical Details

| WORKING AREA | |

|---|---|

| Table set up area | 1120 mm x 260 mm |

| Table load capacity (max.) | 250 kg |

| Number of T-slots | 3 positions |

| T-slot (width x spacing) | 14 mm x 63 mm |

| X-axis travel | 600 mm |

| Y axis travel | 240 mm |

| Z-axis travel | 380 mm |

| VERTICAL MILLING HEAD | |

|---|---|

| Spindle speed (vertical) | 45 1/min - 1660 1/min |

| Spindle mount | DIN 2080 / ISO 40 |

| Throat | 60 mm - 500 mm |

| Vertical spindle-to-table surface distance | 100 mm - 480 mm |

| Milling head swivel range | 360 deg |

| RAPID FEED | |

|---|---|

| Rapid feed Z-axis | 422 mm/min |

| FEED | |

|---|---|

| Feed speed X-axis | 24 mm/min - 402 mm/min |

| Feed speed Y-axis | 24 mm/min - 402 mm/min |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 2,2 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,66 m x 1,5 m x 1,73 m |

| Weight | 1480 kg |

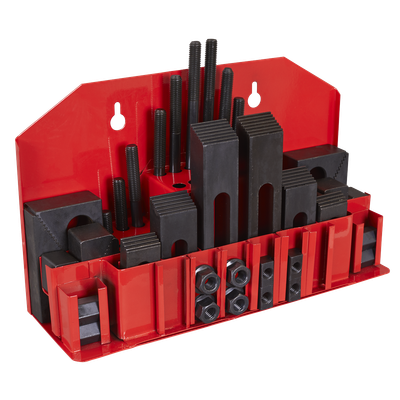

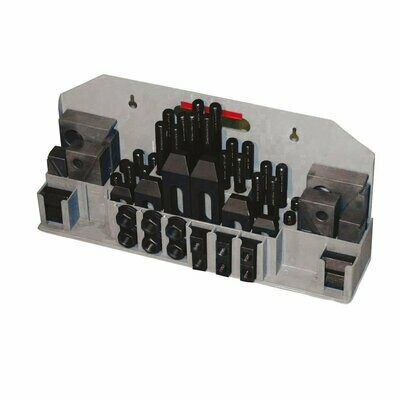

Standard Equipment

- 3-axis position indicator

outer arbor support for horizontal milling

milling chuck with collets 4,5,6,8,10,12,14,16 mm

long cutter arbor Ø 32 mm

coolant system

LED work lamp

operator instructions

Options

Wide range of tooling options available

Please contact us by email if you need pricing information on any tooling optional equipment.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.