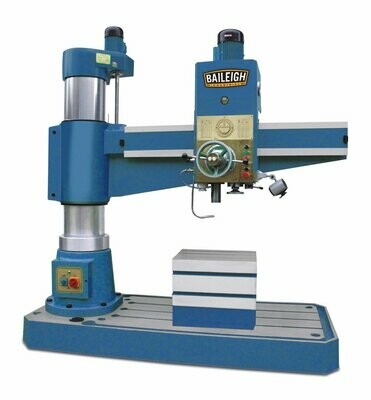

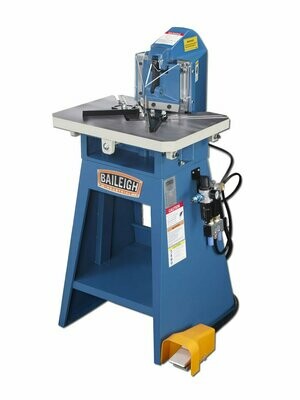

Knuth SSB 50 F Super VT Column Drill Press (Part No. 101673) High Quality Large Capacity, Easy Handling Column Drill Press For Industrial Applications

Knuth SSB 50 F Super VT Column Drill Press

(Part No. 101673 )

High Quality Large Capacity, Easy Handling Column Drill Press For Industrial Applications

Availability. Ex Stock. 2/3 weeks to site. Subject to no prior sales.

Highlights

The drilling machines of the SSB F Super series are the right choice for every workshop, from maintenance to production. The sturdy drilling machines are constructed with a thick-walled column and powerful drives. The spindle speed is infinitely variable and the quill feed has a robust gearbox. Whether via the control panel or touchscreen, all functions are clearly displayed and are easy to use. The clamping table can be moved in height using a motor and facilitates the handling of heavy parts.

- High drilling and thread cutting capacity

- Infinitely variable speed

- Motorized table height adjustment

- Swiveling and rotating setup table

- Fully equipped

Knuth SSB 50 F Super VT Column Drill Press

- Ideal for drilling, countersinking, reaming and tapping

- Heavy construction with thick-walled column

- Base, column, table and gear head are made of premium high-quality cast iron

- Large drill press table with circumferential coolant groove, height adjustment, and ± 45° swivel range

- Table height adjustment via a powerful motorized drive

- The auxiliary gears run in an oil-bath for maximum reliability and minimum wear

- 4 automatic drill feeds with electromagnetic clutch control and automatic shut-off when reaching the limit stop

- Easy handling of the machine ensures effortless operation in a production environment

- Thread-cutting feature is standard

- 8" touchscreen features a rugged, resistant surface

- No programming skills are required for the modern, patented control system

- The infinitely variable spindle speed can be controlled at the display and is easy to read

- The control system assists the operator with the selection of the correct rpm and feed speed

- The system recommends cutting parameters based on bore diameter and material, which also may be accepted automatically

- The depth stop is set electronically at the display

- Measuring units for input and display can be selected by the operator (mm or inch)

- Various alarm screens warn the operator in case of operational errors

- The high-performance coolant system also is activated at the touchscreen

- The system features an operating hour counter

Technical Details

| WORKING AREA | |

|---|---|

| Drilling capacity | 50 mm |

| Tapping capacity, steel | M 30 |

| Table set up area | 580 mm x 460 mm |

| Quill stroke | 200 mm |

| Manual table travel | 530 mm |

| Powered table travel | 410 mm |

| Table swivel range (max.) | ± 45° |

| Column diameter | 180 mm |

| Spindle nose-to-table surface distance | 590 mm |

| Spindle nose-to-foot distance | 1175 mm |

| Throat | 360 mm |

| HEADSTOCK | |

|---|---|

| Speed range | 50 1/min - 2200 1/min |

| Spindle mount | MK 4 |

| FEED | |

|---|---|

| Quill feeds | 0,08; 0,12; 0,17; 0,24; 0,35; 0,50 (6) mm/R |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 2,2 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,15 m x 0,68 m x 2,36 m |

| Weight | 650 kg |

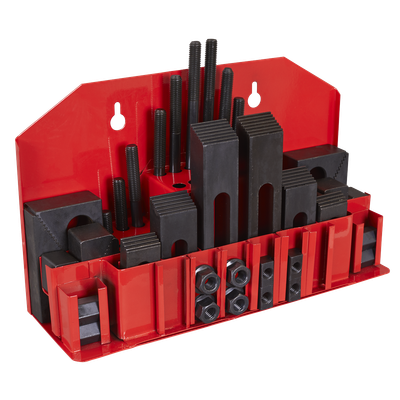

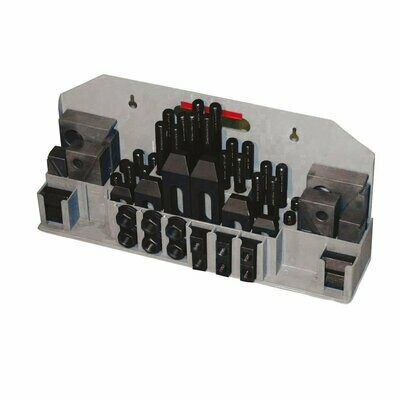

Standard Equipment

touchscreen control panel

tapping unit

protective shield

LED work lamp

coolant system

operating tools

operator manual

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.