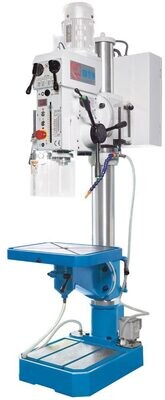

Knuth HFS 73 NC Surface Grinder ( Part No. 122420 ) Automatic and semi automatic grinding with dressing cycle

Knuth HFS 73 NC Surface Grinder

( Part No. 122420 )

Automatic and semi automatic grinding with dressing cycle

Ex Stock Availability .Delivery currently 2 weeks from receipt of order.

Highlights

The HFS NC series is a solution for automatic and semi-automatic surface and flute grinding. This machine offers advantages in terms of precision and efficiency thanks to grinding cycles that can be easily programmed via the touchscreen and the automatic grinding wheel dressing mode. This can be inserted into the machining cycles and compensates dimensions and speed fully automatically. The option of switching between semi-automatic and automatic operation also extends the range of applications from repair workshops and training to series production.

- Automatic grinding wheel dressing cycle

- Magnetic table and built-in demagnetization feature

- Vertical axis with ball screw and servo motor for high precision

- Easy auto-mode programming

- Extensive standard equipment package

Knuth HFS 73 NC Surface Grinder

- Designed for continuous operation at maximum speed, very quiet operation, maximum accuracy and minimal heat accumulation ensure optimum machining results

- Dual guides for linear table motion

- Spindle head and Z-axis move on precision linear guides with preloaded ball screws

- Servo drives on Y- and Z-axis and hydraulic linear table movement can be adjusted via an infinitely variable electronic proportional valve for precise and consistent feed

- 3-step electronic hand-wheel allows for precise positioning of the Y- and Z-axis

- The heavy-duty, rigid grinding spindle head features maintenance-free preloaded high-precision angular ball bearings

- External hydraulic unit and large oil cooler ensures thermal stability

- Automatic central lubrication system

Technical Details

| WORKING AREA | |

|---|---|

| Grinding area (max.) | 720 mm x 300 mm |

| Workpiece weights incl. magnetic clamping plate (max.) | 400 kg |

| Spindle axis-to-table surface distance | 640 mm |

| Dimensions magnetic clamping plate | 700 mm x 300 mm |

| T-slots, width | 14 mm |

| Number of T-slots | 1 positions |

| Division (electronic hand-wheel) Y-axis | 0,001 / 0,005 / 0,01 mm |

| TRAVELS | |

|---|---|

| Travel X-axis | 800 mm |

| Travel Z-axis | 330 mm |

| HEADSTOCK | |

|---|---|

| Spindle speed | 500 1/min - 2300 1/min |

| RAPID FEED | |

|---|---|

| Rapid feed Y-/Z-axis | 0 mm/min - 1200 mm/min |

| FEED | |

|---|---|

| Feed per rotation (electronic hand-wheel) - Y-axis | 0,1 / 0,5 / 1,0 mm |

| Feed per rotation (electronic hand-wheel) - Z-axis | 1,0 / 5,0 / 10 mm |

| Feed speed - X axis (hydraulic) | min, 3 / max, 25 m/min |

| Feed speed Z-axis | 0 mm/min - 1200 mm/min |

| Autom. feed - Micro-feed Y-axis | 0,001 mm - 0,01 mm |

| Autom. feed - Coarse feed Y-axis | 0,005 mm - 0,04 mm |

| Automatic Z-axis feed | 0,1 mm - 25 mm |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 3,7 kW |

| Motor rating hydraulic pump | 1,5 kW |

| Motor rating coolant pump | 0,18 kW |

| Z and y axis servo motor | 0,55 / 0,55 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Grinding wheel dimensions | 400 mm x 127 mm x 40 mm |

| Overall dimensions (length x width x height) | 2,9 m x 1,9 m x 2,5 m |

| Weight | 2500 kg |

Standard Equipment

magnetic clamping plate

coolant system with magnetic separator

central lubrication

hydraulic oil cooler

grinding wheel flange

diamond dresser with holder

balancing station

setup feet

tool box

operator manual

Optional Equipment

cooling water with magnetic and tape filtration for HFS NC

SKU: 251573

Shipping

Fully inclusive shipping rates covering transportation , import customs documentation, duties quoted

for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands and other remote

sites should seek advice prior to order via email. Clients will be responsible for their own site offload

and siting at point of use.

Installation Assistance

We will be pleased to offer a detailed quotation to cover this aspect of your investment subject to

being forwarded full details of site postcode, access, site conditions and floorspace availability.

Knuth technicians are busy worldwide and have experience in a wide variety of industrial facilities.

We are also likely to request provision of cranes, fork lift assistance etc by our clients as required.

Finance Availability

Looking to finance your equipment?We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.