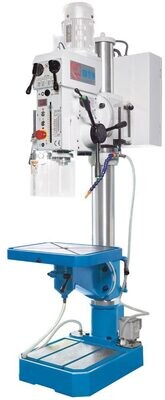

Knuth HFS 40100 F Advance Surface Grinding Machine ( Part No. 124930 ) High precision and ease of use for maximum production efficiency

Knuth HFS 40100 F Advance Surface Grinding Machine

( Part No. 124930 )

High precision and ease of use for maximum production efficiency

Delivery currently 26 weeks from receipt of order.

Highlights

Knuth HFS F Advance Surface Grinder

The HFS F Advanced series is the latest development of our proven surface grinding machines, which have proven themselves in many companies for decades. Although surface grinding is a common machining process, the machines in this series set a high standard with their extensive range of standard accessories as a turnkey solution. New are the advanced operating functions that have been implemented with technology from Siemens. These machines are the best choice for customers for whom conventional is not enough and CNC is too much.

- Magnetic table with integrated degaussing function

- Vertical axis with ball screw and servo motor for high precision

- Easy programming in automatic mode with Siemens PLC and touch screen

- Extensive standard equipment

Range - 5 model series

HFS 2550 F Advance Surface Grinder , 508 x 254 mm Table

HFS 3063 F Advance Surface Grinder , 635 x 305 mm Table

HFS 4080 F Advance Surface Grinder , 813 x 406 mm Table

HFS 30100 F Advance Surface Grinder , 1020 x 300 mm Table

HFS 40100 F Advance Surface Grinder , 1020 x 406 mm Table ( Quoted Model )

Please email us if you are interested in any other models in the series and require price and delivery details.

Knuth 40100 F Advance Surface Grinder

The HFS F Advanced series is the latest development of our proven surface grinding machines, which have proven themselves in many companies for decades. Although surface grinding is a common machining process, the machines in this series set a high standard with their extensive range of standard accessories as a turnkey solution. New are the advanced operating functions that have been implemented with technology from Siemens. These machines are the best choice for customers for whom conventional is not enough and CNC is too much.

- Magnetic table with integrated degaussing function

- Vertical axis with ball screw and servo motor for high precision

- Easy programming in automatic mode with Siemens PLC and touch screen

- Extensive standard equipment

Detail

- The cast iron machine frame convinces with stability and torsional rigidity, precise guides and excellent workmanship

- All guideways are reliably supplied with lubricant by an automatic central lubrication system

- The working area is protected by an easily accessible housing

- The powerful coolant pump is combined with a suction unit and thus binds the grinding dust and aerosol that arise during processing

- The grinding spindle is large, dynamically balanced, completely sealed and permanently lubricated

- Preloaded precision bearings enable maximum grinding performance and reliability for many hours of production

- The high-quality ball screw and the powerful servomotor guarantee precision and repeatability of the positioning in the Y-axis

- The machine has an electronic handwheel for set-up work and for manual movement of the grinding spindle

- In automatic mode, the values specified by the operator in roughing and finishing mode, the number of spark-out strokes and the retraction to the starting point are processed automatically

- Excellent running smoothness with low temperature build-up ensures the best work results in continuous operation

- The hydraulic longitudinal movement of the table is infinitely adjustable, very constant and with a soft change of direction

- The external hydraulic unit with oil cooler unit ensures perfect temperature stability in continuous operation

- The standard, large magnetic clamping plate enables distortion-free clamping

- The control unit integrated in the machine's electrical system enables simple operation and thus fast clamping and demagnetizing for the best production efficiency

grinding spindle

programming

hydraulics

magnetic chuck

Siemens Touchscreen

Technical Details

| WORKSPACE | |

|---|---|

| Workpiece, weight (max.) | 600kg |

| Distance spindle nose - table surface | 580mm |

| table dimensions | 1020mm x 406mm |

| Dimensions magnetic chuck | 1000mm x 400mm |

| Scale ring division Y-axis | 0.005mm |

| Scale ring graduation Z-axis | 0.02mm |

| auto. Cross feed Z-axis | 0.1mm - 8mm |

| rotation speed | 1450 rpm |

| auto. vertical delivery | 0.005mm - 0.05mm |

| TRAVERSE PATHS | |

|---|---|

| X axis travel | 1130mm |

| Y axis travel | 450mm |

| FEED | |

|---|---|

| Rapid traverse Y-axis | 480mm/min |

| Rapid Z axis | 990mm/min |

| hydraulic Feed X axis | 7m/min - 23m/min |

| DRIVE POWER | |

|---|---|

| Main drive engine power | 4kW |

| Motor power drive Y-axis | 0.5kW |

| Engine power hydraulic pump | 2.2kW |

| MASS AND WEIGHT | |

|---|---|

| Dimensions (length x width x height) | 4.4m x 2.4m x 1.9m |

| Weight | 3700kg |

| grinding wheel dimensions | 350mm x 40mm x 127mm |

Standard Equipment

2-axis position display

Working area cover

Balancing stand

Balancing shaft

Automatic central lubrication

Operating tool Adjusting screws

Electronic

handwheel

Grinding

wheel Grinding wheel dresser

Grinding wheel flange

Magnetic chuck

LED work

light Coolant device and extraction system

Operating instructions

Siemens PLC control with touchscreen

demagnetization

Optional Equipment

fine-pole magnetic chuck HFS 40100 F Advance SKU: 253463

Please contact us if any of the optional equipment is of interest for further information

Operator Training

Operator training available in showroom subject to quotation prior to delivery.

Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation , import customs documentation, duties quoted

for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands and other remote

sites should seek advice prior to order via email. Clients will be responsible for their own site offload

and siting at point of use.

Installation Assistance

We will be pleased to offer a detailed quotation to cover this aspect of your investment subject to

being forwarded full details of site postcode, access, site conditions and floorspace availability.

Knuth technicians are busy worldwide and have experience in a wide variety of industrial facilities.

We are also likely to request provision of cranes, fork lift assistance etc by our clients as required.

Finance Availability

Looking to finance your equipment?We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.