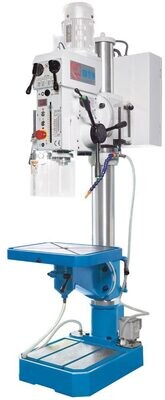

Knuth RSM 500 A Conventional Cylindrical Grinding Machine ( Part No. 302430 ) High precision cylindrical grinding machine for inside and outside machining

Knuth RSM 500 A Conventional Cylindrical Grinding Machine

( Part No. 302430 )

High precision cylindrical grinding machine for inside and outside machining

EX stock. Delivery currently 1 weeks from receipt of order

Highlights

RSM A Series Conventional Cylindrical Grinding Machines

The machine frames of the RSM series are characterized by a heavy design and long, supporting guideways. The table can be swiveled and the finely adjustable hydraulic feed moves smoothly in the longitudinal direction. A large scale ring on the handwheel of the X-axis facilitates precise infeed and the zero stop guarantees compliance with the desired dimension. The standard position indicator with linear scales is used to check the actual values. The headstock is rotated 180 degrees for internal grinding. An extensive accessory package is standard.

Range - 2 model in series

RSM 500 A 500 mm Grinding length external , 8 - 200 mm diameter / Quoted Model

RSM 800 A 800 mm Grinding length external , 8 - 200 mm diameter

Please email us if you are interested in any other models in the series and require price and delivery details.

Knuth RSM 500 A Conventional Cylindrical Grinding Machine

The machine frames of the RSM series are characterized by a heavy design and long, supporting guideways. The table can be swiveled and the finely adjustable hydraulic feed moves smoothly in the longitudinal direction. A large scale ring on the handwheel of the X-axis facilitates precise infeed and the zero stop guarantees compliance with the desired dimension. The standard position indicator with linear scales is used to check the actual values. The headstock is rotated 180 degrees for internal grinding. An extensive accessory package is standard.

- Internal and external grinding

- Hydrostatic bearings for high surface quality

- Swiveling headstock for conical grinding of short parts

- Integrated rapid feed on Z-axis with manual return

- Extensive package of standard accessories

Detail

- Proven and extremely rigid machine frame made of premium cast-iron - this machine’s high intrinsic weight, diligent design and production create optimum conditions for excellent grinding and sanding results

- Hydraulic linear feed features very precise, infinitely variable micro-feed

- High-precision guideways of linear and transverse movement consisting of combined V-guides and box ways

- Hydraulic adjustment of the grinding headstock simplifies set-up, workpiece exchanges and reduces downtime

- Grinding spindle with segmented high-precision bearing, adjustable and low maintenance

- Work spindle speeds are infinitely variable and can be easily adjusted and optimized during the machining process

- Machine table swivels for taper grinding

- Hydraulic tailstock with foot switch

Technical Details

| WORKING AREA | |

|---|---|

| Center height | 135 mm |

| Workpiece length (max.) | 650 mm |

| Grinding length | 500 mm |

| Grinding diameter | 8 mm - 200 mm |

| Inside grinding diameter without rest | 10 mm - 100 mm |

| Workpiece weight between centers (max.) | 50 kg |

| Inside grinding depth | 125 mm |

| Table swivel range (max.) | -3° / +9° R / L |

| Wheel speeds | 38 m/s |

| FEED | |

|---|---|

| Table feed, infinitely variable | 0,1 m/min - 4 m/min |

| Feed per scale division X-axis | 0,005 mm |

| GRINDING HEADSTOCK | |

|---|---|

| Inside grinding spindle speed | 16000 1/min |

| Grinding headstock swivel range (r+l) | ± 30° |

| TAILSTOCK | |

|---|---|

| Tailstock taper | 4 MT |

| MEASURES AND WEIGHTS | |

|---|---|

| Grinding wheel dimensions | 400 mm x 50 mm x 203 mm |

| Grindstone dimensions, inside grinding (max.) (length x width) | 50 mm x 25 mm x 13 mm |

| Grindstone dimensions, inside grinding (min.) (length x width) | 17 mm x 20 mm x 6 mm |

| Overall dimensions (length x width x height) | 2,5 m x 1,6 m x 1,5 m |

| Weight | 2500 kg |

Standard Equipment

2-axis position indicator

internal grinding equipment

3-jaw chuck Ø 200 mm

chuck flange

balancing station

balancing mandrel

dress equipment

center point

grinding wheel flange

coolant system

open rest

closed rest

work lamp

operating tools

operator instructions

drivers

Operator Training

Operator training available in showroom subject to quotation prior to delivery.

Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation , import customs documentation, duties quoted

for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands and other remote

sites should seek advice prior to order via email. Clients will be responsible for their own site offload

and siting at point of use.

Installation Assistance

We will be pleased to offer a detailed quotation to cover this aspect of your investment subject to

being forwarded full details of site postcode, access, site conditions and floorspace availability.

Knuth technicians are busy worldwide and have experience in a wide variety of industrial facilities.

We are also likely to request provision of cranes, fork lift assistance etc by our clients as required.

Finance Availability

Looking to finance your equipment?We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.