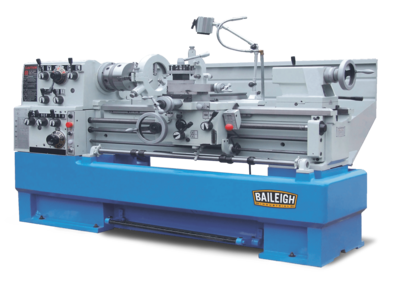

Knuth Turnado 280/1500 PRO Conventional Lathe ( SKU 320564 )

Knuth Turnado 280/1500 PRO Conventional Lathe ( SKU 320564 )

Turnado PRO series are the modern version of the classic lathe.

Ex Stock Availability, 4 weeks, Subject to No Prior Sales.

Highlights

Knuth Turnado 280/1500 PRO Conventional Lathe ( SKU 320564 )

The machines of the Turnado PRO series are the modern version of the classic lathe. The PRO models are the latest generation of our universal lathes, which have been tried and tested for 20 years. With constant cutting speed, rapid traverses and an extended speed range that can be controlled by an inverter, these models are characterized by high-performance machining, excellent surface quality and time efficiency. They are easy to recognize by the new ergonomic cladding design, which integrates all functions into an overall concept.

- Infinitely variable speed range

- Apron with rapid feed motor

- Extensive standard equipment

- Constant cutting speed

Product Detail

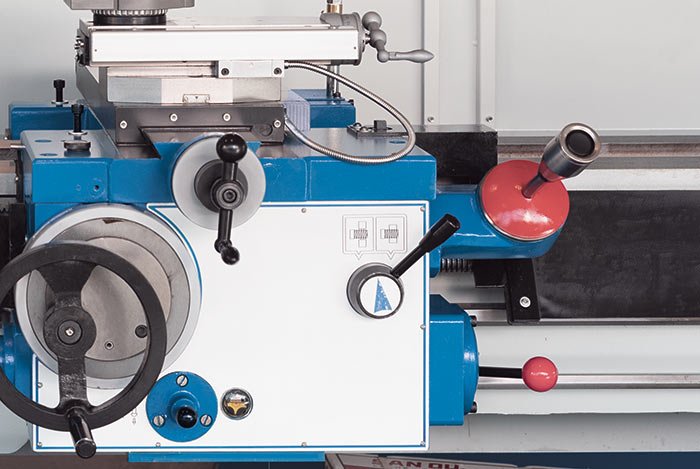

- With a new apron design, rapid feed and a modern ergonomic machine frame, the Turnado Lathe PRO series continues its success story

- A heavily ribbed machine bed, rigid headstock and a massive one-piece cast-iron stand form a solid machine base

- Removable bridge allows machining of short workpieces with large diameters

- Back-gearing and an advanced electronic control technology of the powerful main spindle drive ensure high torque and a wide range of speeds

- High-precision pre-loaded spindle bearings ensure superior concentricity and load capacity

- All guides are adjustable

- Gears, transmission shafts, and guideways are hardened and ground to guarantee quiet operation and long tool life

- The apron runs in an oil bath for low maintenance and high reliability

- A central lubrication system inside the support supplies all guideways with lubrication and simplifies maintenance

- Micrometer bed stop ensures high repeatability on the Z-axis

- The tailstock can be adjusted sideways for taper turning

- The extensive features of the X.Pos Position Indicator are complemented here with a digital speed indicator and an easy to program auxiliary function

- Constant cutting speed: During face turning, the spindle speed automatically adapts to the changing workpiece diameter – the constant cutting speed at the cutting edge of the turning tool ensures superior turning results with quality comparable to CNC lathes

Technical Details

| Working area | |

|---|---|

| Center width | 1500 mm |

| Center height | 280 mm |

| Turning-Ø over bed | 560 mm |

| Turning diameter over gap bridge | 785 mm |

| Turning-Ø over support | 355 mm |

| Gap bridge length | 170 mm |

| Bed width | 350 mm |

| Travels | |

|---|---|

| Travel X-axis | 316 mm |

| Travel Z1-axis | 130 mm |

| Swing range of top slide | ± 52° |

| Headstock | |

|---|---|

| Speed range, low | 25 1/min - 200 1/min |

| Speed range, high | 200 1/min - 1600 1/min |

| Spindle bore | 80 mm |

| Spindle mount | Camlock D1-8 |

| Spindle taper | 7 MT |

| Feed | |

|---|---|

| Feed X-axis | 0,02 mm/R - 0,573 mm/R |

| Feed Z-axis | 0,059 mm/R - 1,646 mm/R |

| Threading | |

|---|---|

| Threading, metric | 0,2 mm - 14 mm |

| Threading, diametric | (50) 4-112 DP |

| Threading, module | 0,1 mm - 7 mm |

| Threading, whitworth | (60) 2-112 TPI |

| Tailstock | |

|---|---|

| Tailstock quill diameter | 75 mm |

| Tailstock taper | MK 5 |

| Tailstock quill stroke | 180 mm |

| Tailstock traverse adjustment | ± 12 mm |

| Drive capacity | |

|---|---|

| Motor rating main drive | 7,5 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 2,84 m x 1,15 m x 1,46 m |

| Weight | 2370 kg |

Controls & Software

3-axis position indicator, X.pos 3.2 VC

- Integrating multiple functions, this new generation of 3 axis digital readouts significantly offer a much better control over the machining processes, greatly decreasing down-times and error rates

- Integrating multiple functions, this new generation of 3 axis digital readouts significantly offer a much better control over the machining processes, greatly decreasing down-times and error rates

- It features a totally sealed enclosure made of high quality polyester film which protects it against hazardous enviroments in shop floors, such as dust or fumes and offers excellent chemical resistance to most commonly used industry solvents

- The optical scales provide 5 micron resolution (0.005 mm) with outside cover from aluminum for protection against oil, coolant and chips.

Basic Functions

- Resolution of 0,005 mm

- Spindle control ON/OFF

- Unit measurement conversion Inch / Metric

- Setting / Reseting current position

- Coordinate display switching ABS / INC

- Radius / Diameter display

- Z1/Z2 Axes summing

- Pocket calculator functions

Extended Functions

- Axis position is maintained when display is turned off

- Hole circle pattern calculation

- Radius / diameter toggle

- Reference function for tool gauging

- Taper turning function

Constant cutting speed

- Allows you to have constant cutting speed during - the spindle speed automatically adjusts based on the turning diameter

Standard Equipment

Optional Equipment

Extensive range of optional tooling available for this machine

4-Jaw Lathe Chuck 315/8 2800 min-1 / Topturn SKU: 146483

Quick-Set Spindle Bore Stop Size 9 79-91mm SKU: 103025

Tool Holder WCD 32x150 SKU: 103301

Tool Holder WCD 32x170 SKU: 103302

Tool Holder WCD 40x150 SKU: 103303

Tool Holder WCD 40x170 SKU: 103304

Tool Holder WCD 45x170 SKU: 103305

Tool Holder WCH 50x160 SKU: 103307

Tool Holder WCJ 40x160 SKU: 103308

Tool Holder WCJ 50x160 SKU: 103309

Cut-off insert holder WCA-A3a SKU: 103310

Reduction Sleeve MT 5/2 SKU: 103835

Reduction Sleeve MT 5/3 SKU: 103840

Reduction Sleeve MT 5/4 SKU: 103845

3-jaw chuck 315mm D1-8 (cast iron) SKU: 116523

soft top jaws for 3-jaw-chuck 315mm (116504/116505) SKU: 116553

4-Jaw Lathe Chuck Cast Iron 315 mm SKU: 116625

soft top jaws for 4-jaw-chuck 315mm (116604-116605) SKU: 116653

4-jaw independent chuck 315mm D1-8 SKU: 116674

soft top jaws for 4-jaw- chuck 315mm SKU: 116692

Clamped Turning Tool Set 25 mm SKU: 108670

Coolant Concentrate 5 Ltr . SKU: 103184

Live Centers MT 5 SKU: 106760

Power Worker Metal Cutter SKU: 123040

Knurl Holder SKU: 108520

Knurl Set, angles SKU: 108521

Contact us via email for price details on our optional tooling.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

The certificate holder's Management System corresponds to standard ISO 9001:2015.