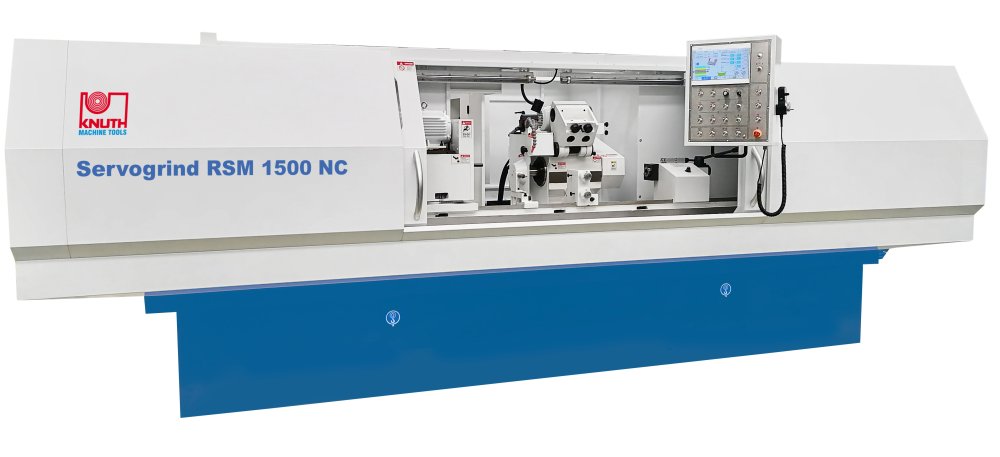

Knuth Servogrind RSM 1500 NC Cylindrical Grinding Machine (SKU : 124961) For long and heavy workpieces.

Knuth Servogrind RSM 1500 NC Cylindrical Grinding Machine

(SKU : 124961)

Ex Stock Availability . Delivery currently 2/3 weeks from receipt of order.

Highlights

Servogrind RSM 1500 NC Cylindrical Grinding Machine

The Servogrind® RSM NC is a precision cylindrical grinding machine for long and heavy workpieces. Instead of a conventional hydraulic unit, however, the series has a modern servo motor drive for both axes, which raises the dynamics, efficiency and precision of the machine to a new level. The series is suitable for both single part and small batch production and offers additional flexibility with the internal grinding device. The solid construction with a large machine bed, ground guideways and powerful drives for the work spindle and grinding spindle has proven itself many times over. The modern NC control with touchscreen requires no programming knowledge, simplifies operation and increases productivity.

- NC control with touchscreen

- Grinding cycles for internal and external cylindrical grinding

- Servomotors in both axes

- Swivelling table and swivelling work spindle

- Extensive range of standard accessories

Product Details

Machine bed

- The heavy machine bed is designed for high-precision machining of large and heavy workpieces

- The swiveling work table runs on precision-ground, wide and long v-block guides ensuring excellent vibration damping

- With this design the total weight of table and workpiece is distributed evenly over a large area, which ensures high rigidity and minimal tilting torque

- The robust tailstock ensures rigidity and accuracy during clamping of a workpiece between centers

Feed

- The use of servo-conventional feed technology instead of a hydraulic system results in a more consistent and vibration-free advance of the work table

- Premium servo drives allow axis movements with the precision and dynamics of modern CNC machines

- All feed settings can be set with high accuracy and repeatability, and electronic stop gauges provide precise travel limits

- Preloaded ball screws on all axes ensure reduced friction and significantly lower breakaway torques resulting in faster and more precise movements

- The significantly reduced heat build-up leads to more consistent conditions during continuous operation and long-term wear reduction

- Drives, spindles, and measuring systems are totally enclosed or mounted in protective enclosures and virtually maintenance-free

Grinding Headstock

- The headstock runs on premium linear guides that allow maximum positioning accuracy even at the slightest axis movements

- An extensively supported grinding spindle guarantees maximum precision and surface quality for roughing and finishing work

- The inside grinder can be pivoted into the work area as needed and is driven by a separate motor

Work spindle drive

- The work spindle headstock swivels to one side, and the spindle speed is infinitely variable

- A 3-jaw chuck with 200 mm diameter and superior concentricity is included in this series’ standard equipment

Equipment

- The totally enclosed work area features large doors for easy access and easy loading and unloading

- All controls are arranged centrally on a control panel, and all technical parameters are displayed on the touch screen monitor

- LED lights ensure good visibility and safety during machining operations

- An automatic central lubrication system simplifies maintenance and reduces the operator's workload

- The mobile electronic hand-wheel significantly simplifies machine setup and reduces down times

- A rest for machining of long workpieces is included in the machine’s standard equipment

- A powerful coolant system, dresser, grinding wheel balancer, and operating tools also are included in the standard package

NC control

- The NC positioning control allows the combination of roughing, finishing and spark-out in one operation

- Individual grinding cycles can be programmed via a touchscreen control, no programming knowledge required

- The HMI provides easy to use control menus for every longitudinal and traverse cylindrical grinding application

- Detailed graphics assist the user during data entry and show the current status during machining operations

Technical Details

| Working area | |

|---|---|

| Center height | 180 mm |

| Grinding diameter | 8 mm - 320 mm |

| With steady rest | 15 mm - 150 mm |

| Grinding length | 1500 mm |

| Inside grinding diameter with rest | 35 mm - 100 mm |

| Inside grinding diameter without rest | 30 mm - 100 mm |

| Inside grinding depth | 125 mm |

| Workpiece weight between centers (max.) | 150 kg |

| Grinding wheel feed (min.) | 0,001 mm |

| Table swivel range (max.) | -2° / +9° |

| Wheel speeds | 45 m/s |

| Work spindle speeds | 50 Hz: 25-380 1/min |

| Travels | |

|---|---|

| Grinding head travel | 250 mm |

| Feed | |

|---|---|

| Table feed, infinitely variable | 0,03 m/min - 6 m/min |

| Headstock | |

|---|---|

| Working headstock swivel range | 90 deg |

| Working spindle taper | 4 MT |

| Chuck diameter | 200 mm |

| Work spindle speeds | 25 1/min - 500 1/min |

| Grinding headstock | |

|---|---|

| Grinding spindle speed | 2140 1/min |

| Grinding headstock swivel range (r+l) | 10° |

| Inside grinding spindle speed | 10000 1/min |

| Tailstock | |

|---|---|

| Tailstock taper | 4 MT |

| Tailstock quill stroke | 30 mm |

| Drive capacity | |

|---|---|

| Motor rating - grinding spindle | 4 kW |

| Motor rating inside grinding | 1,1 kW |

| Motor rating - headstock / coolant pump | 1,5 / 0,13 kW |

| Measures and weights | |

|---|---|

| Grinding wheel dimensions | 400 mm x 50 mm x 203 mm |

| Grindstone dimensions, inside grinding (max.) | 50 mm x 40 mm x 16 mm |

| Grindstone dimensions, inside grinding (min.) | 20 mm x 20 mm x 6 mm |

| Overall dimensions (length x width x height) | 5,1 m x 2,2 m x 1,8 m |

| Weight | 3700 kg |

Standard Equipment

NC control with touchscreen

Shipping

Fully inclusive shipping rates covering transportation , import customs documentation, duties quoted

for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands and other remote

sites should seek advice prior to order via email. Clients will be responsible for their own site offload

and siting at point of use.

Installation Assistance

We will be pleased to offer a detailed quotation to cover this aspect of your investment subject to

being forwarded full details of site postcode, access, site conditions and floorspace availability.

Knuth technicians are busy worldwide and have experience in a wide variety of industrial facilities.

We are also likely to request provision of cranes, fork lift assistance etc by our clients as required.

Finance Availability

Looking to finance your equipment?We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.