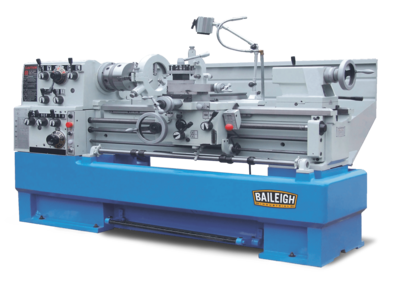

Knuth Basic 170 Super Pro Conventional Horizontal Lathe

Knuth Basic 170 Super Pro Conventional Horizontal Lathe

Delivery lead time 2 weeks from receipt of order.

Highlights

Basic 170 Super Pro ( SKU : 300814)

For many years the Basic series has been the reliable mechanic's lathes that have been used in countless workshops and training centers. The new PRO version offers improved performance and ergonomics, more standard equipment and also the design has been improved, to meet the demands of todays users.

- Modern ergonomic design

- Large spindle bore

- Machine base with storage space

- Extensive standard equipment

- Coolant system

Product Details

- The fully equipped Basic PRO with its modern ergonomic design meets all requirements for universal applications in the areas of repairs, training and production

- The lathe bed is made of high-quality cast-iron for maximum stability and rigidity

- All gears, transmission shafts, and guideways are hardened and ground to guarantee very quiet operation and long tool life

- Wide guideways are hardened and ground to reduce wear and allow readjustments for long-term accuracy

- Readjustable spindle bearings ensure high precision and low wear for a long service life

- Gears and apron run in an enclosed oil bath for low maintenance

- Safety interlock to prevent simultaneous operation of lead screw and feed shaft feed

- Stainless steel covers on lead screw and feed shaft ensure safety without the usual restrictions, while also preventing contamination and early wear

- The tailstock can easily be positioned on the machine bed and moved sideways for taper turning

- High-performance coolant system is included

- The machine base features ample storage space for accessories and tools, including a chip tray that can be removed at front

- The X.Pos position indicator provides easy to program auxiliary functions

Technical Details

| WORKING AREA | |

|---|---|

| Center width | 1000 mm |

| Center height | 179 mm |

| Turning diameter over bed | 360 mm |

| Turning-Ø over support | 223 mm |

| Bed width | 187 mm |

| TRAVELS | |

|---|---|

| Travel X-axis | 185 mm |

| Travel Z1-axis | 95 mm |

| HEADSTOCK | |

|---|---|

| Spindle speed | 70 1/min - 2000 1/min |

| Spindle bore | 52 mm |

| Spindle mount | Camlock D1-5 |

| Spindle taper | 6 MT |

| FEED | |

|---|---|

| Feed X-axis | 0,0291 mm/R - 2,035 mm/R |

| Feed Z-axis | 0,0406 mm/R - 2,842 mm/R |

| THREADING | |

|---|---|

| Threading, metric | 0,2 mm - 14 mm |

| Threading, whithworth | 2 TPI - 56 TPI |

| Threading, diametric | 8 DP - 56 DP |

| Threading, module | 0,2 MP - 3,5 MP |

| TAILSTOCK | |

|---|---|

| Tailstock quill diameter | 42 mm |

| Tailstock taper | 3 MT |

| Tailstock quill stroke | 100 mm |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 1,5 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,9 m x 0,76 m x 1,6 m |

| Weight | 650 kg |

Controls & Software

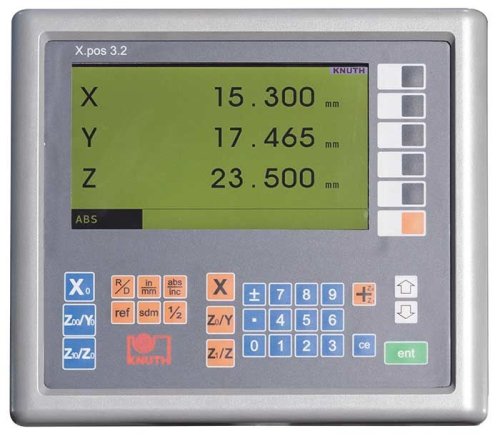

3-axis position indicator X.Pos 3.2

- Integrating multiple functions, this new generation of 3 axis digital readouts significantly offer a much better control over the machining processes, greatly decreasing down-times and error rates

- Integrating multiple functions, this new generation of 3 axis digital readouts significantly offer a much better control over the machining processes, greatly decreasing down-times and error rates

- It features a totally sealed enclosure made of high quality polyester film which protects it against hazardous enviroments in shop floors, such as dust or fumes and offers excellent chemical resistance to most commonly used industry solvents

- The optical scales provide 5 micron resolution (0.005 mm) with outside cover from aluminum for protection against oil, coolant and chips.

Basic Functions

- Resolution of 0,005 mm

- Spindle control ON/OFF

- Unit measurement conversion Inch / Metric

- Setting / Reseting current position

- Coordinate display switching ABS / INC

- Radius / Diameter display

- Z1/Z2 Axes summing

- Pocket calculator functions

Extended Functions

- Axis position is maintained when display is turned off

- Hole circle pattern calculation

- Radius / diameter toggle

- Reference function for tool gauging

- Taper turning function

Constant cutting speed

- Allows you to have constant cutting speed during - the spindle speed automatically adjusts based on the turning diameter

Standard Equipment

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

The certificate holder's Management System corresponds to standard ISO 9001:2015.