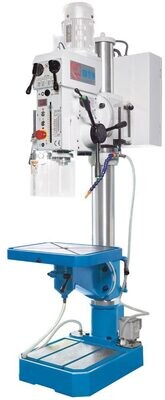

Knuth B150 Belt Sander ( Part No. 102886 ) Industrial Belt Sander for surface edge and radii grinding

Knuth B150 Belt Sander

( Part No. 102886 )

Industrial Belt Sander for surface edge and radii grinding

Ex Stock Availability .Delivery currently 2 weeks from receipt of order.

Highlights

The heavy belt grinder has a large grinding surface with an endless grinding belt that runs over a large contact roller. The angle of the grinder can be adjusted horizontally and connected to a dust extraction system via a nozzle. This belt grinder series has a particularly powerful main drive, ideal for grinding flat and straight surfaces or for chamfering and deburring edges. The contact roller is also ideal for grinding outer and inner radii or angles on narrow workpiece ends.

- For precision grinding of tube unions

- Contact roll for grinding of shaft ends

- Longitudinal grinding surface for deburring

- Suitable for stainless steel and aluminum

- Ready for vacuum exhaust connection

Product Detail

- Excellent grinding results due to minimal vibration during sanding belt operation and rigid design of all components

- The wide contact roll is ideal for grinding edges, points and radii

- Adjustable grinding support with adjustable eye protection for maximum accuracy and safety

- One cover encloses the longitudinal grinding surface while it is not in use

- Grinding belts can be changed within seconds via a quick-change vise, no tools required

- Chip collectors help keep the work environment clean

Technical Details

| WORKING AREA | |

|---|---|

| Contact wheel | 200 mm x 150 mm |

| Sanding area | 530 mm x 150 mm |

| Belt speed | 33 m/s |

| Speed | 2800 1/min |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 4 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Driving roller (dimensions) | 225 mm x 150 mm |

| Overall dimensions (length x width x height) | 1,05 m x 0,62 m x 1,27 m |

| Weight | 128 kg |

Standard Equipment

base

1 sanding belt

support table

safety observation shield

operator instructions

Optional Equipment

Sanding belts

- Metal grinding wheel with high chip-removal rate for flat surface and light contour grinding

- Universal use in various fields of metalworking

- Cost-effective machining and long tool life due to highly resistant corundum

- Medium flexible cotton layer on X for smooth machining operation

- Consistently uniform grinding pattern

Shipping

Fully inclusive shipping rates covering transportation , import customs documentation, duties quoted

for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands and other remote

sites should seek advice prior to order via email. Clients will be responsible for their own site offload

and siting at point of use.

Installation Assistance

We will be pleased to offer a detailed quotation to cover this aspect of your investment subject to

being forwarded full details of site postcode, access, site conditions and floorspace availability.

Knuth technicians are busy worldwide and have experience in a wide variety of industrial facilities.

We are also likely to request provision of cranes, fork lift assistance etc by our clients as required.

Finance Availability

Looking to finance your equipment?We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.