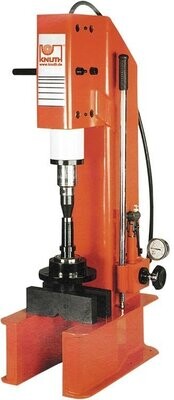

Knuth BO 90 CNC Milling & Boring Machine ( Part No. 180027 ) Modern , compact and powerful with rotating setup table

Knuth BO 90 CNC Milling & Boring Machine

( Part No. 180027 )

Modern , compact and powerful with rotating setup table

Availability. Currently 6 months from receipt of order. Subject to no prior sales.

Highlights

Knuth BO 90 CNC Milling & Boring Machine

The BO 90 CNC drilling and milling machine is designed for horizontal drilling and milling of workpiece weights of up to one ton. For multi-sided machining, the clamping table can be positioned manually in 5 degree steps. The BT 40 spindle holder has automatic tool clamping and the tried and tested Siemens 828 D control system meets all the requirements of a modern CNC solution in terms of programming and handling. Experienced users will quickly become familiar with the SINUMERIK Operate user interface, which Siemens uses throughout up to the SINUMERIK 840D.

- Compact machine design

- Powerful main motor

- Manual rotary table with 5° steps indexing

- Siemens 828D control for advanced machining

Details

Highlights

- A Siemens 828 D control with servo-driven axes meets all requirements of an advanced CNC concept in programming and handling

- Table load capacity 1.000 kg

- Multi-sided machining in one clamping by manually indexable rotary table, divisible in 5° steps

- Provides long travels on all axes and high table load capacity for machining of large parts

Machine Design

Spindle

- Heavy-duty cast-iron machine frame plus wide guideways for optimum drilling and milling work results

- Precision preloaded ball screws in all axes ensure high accuracy with low wear and maintenance

- BT 40 spindle mount with automatic tool clamping

- Max. Spindle speed 6.000 1/min

Siemens 828 D Basic control

SINUMERIK 828 D – The workhorse in the compact class of CNCs

Highlights

- Compact, robust, maintenance-free control panel-based CNC

- Comfortable program and parameter input via QWERTY keyboard

- Maximum machining precision

- Intelligent kinematic transformations for machining of cylindrical parts, and for angled workpiece levels

- SINUMERIK MDynamics with the new Advanced Surface feature: for perfect part surfaces and shortest machining times in mold making applications

- ProgramGUIDE: fastest machining time and maximum flexibility for large series productions

- Unique spectrum of technology cycles - from milling contours with residual material recognition to process measurements

- Animated Elements: unique operation and programming assistance with animated sequences

- Modern data transfer options via USB stick, CF card and network (Ethernet)

CNC hardware

- Control-panel based high-performance CNC Control

- Robust front control panel made of magnesium die-casting

- Integreated full-size QWERTY keyboard

- Maintenance-free design (no buffer battery required)

CNC performance data and functions

- Dynamic feed-forward control

- Linear, circular and helical interpolation

- Tapping without compensating chuck, plus thread cutting

- Toggle between inch and metric units

- FRAME concept for individual coordinate transformations, rotations, scaling and mirroring

- 100 adjustable zero offsets

- Synchronous actions and quick help function output

CNC technology cycles

- Large selection of drilling cycles

- Large selection of milling cycles for standard geometry

- Large selection of position patterns for drilling and milling operations

- High-speed settings for mold making applications

- Geometry calculator for free contour input

- Machining cycle for contour pockets / contour spigots with isolated contours

Graphic features

- Graphical online help system, similar to PC system

- Graphical CNC simulation with level display

CNC tool management

- Display of tool and magazine data on one screen

- Tool management with plain-text tool names

- Loading/unloading feature for easy magazine assignment

- Tool management with tool life monitoring

- 10.4“ TFT color monitor

Technical Details

| WORKING AREA | |

|---|---|

| Drilling capacity | 30 mm |

| Finish bore | 200 mm |

| Milling capacity | 55 cm³/min |

| Table load capacity | 1000 kg |

| Table dimensions | 630 mm x 800 mm |

| Number of T-slots | 6 positions |

| T-slots, width | 18 mm |

| Spindle axis-to-table surface distance | 570 mm |

| Table rotation range (5° units) | 360 |

| TRAVELS | |

|---|---|

| Travel X-axis | 700 mm |

| Travel Y-axis | 510 mm |

| Travel Z-axis | 800 mm |

| HEADSTOCK | |

|---|---|

| Spindle speed | 10 1/min - 6000 1/min |

| Spindle mount | BT 40 |

| FEED | |

|---|---|

| Feed speed X-axis | 1 mm/min - 2000 mm/min |

| Feed speed Y-axis | 1 mm/min - 2000 mm/min |

| Feed speed Z-axis | 1 mm/min - 2000 mm/min |

| ACCURACIES | |

|---|---|

| Positioning accuracies | ± 0,008 mm |

| Repeatabilities | ± 0,005 mm |

| Angular accuracy | ± 3" |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 11 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 3,55 m x 2,35 m x 2,1 m |

| Weight | 4800 kg |

Standard Equipment

Siemens 828 D Basic control

pneumatic rotary table

electronic hand-wheel

halogen lights

central lubrication

drill chuck 3-16 mm / B18

tool-holder bits MT4 / B18

reducing sleeves MT3, MT4, MT5

foundation bolts

operating manual and programming instructions

Options

Tooling options available

E-BO 90 CNC Spare part package for 180027 SKU 259116

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.