Knuth LabCenter 260 (Part No . 181615) Compact, mobile and professional for laboratories and training

Knuth LabCenter 260

(Part No . 181615)

Ex Stock Availability.Currently 4 weeks from receipt of order.Subject to no prior sales

Highlights

The LabCenter is ideal for CNC training, but also for the production of small workpieces. The compact and mobile CNC machining center represents the full range of functions of a large production machine. The main spindle rotates continuously variable up to 5000 revolutions and the Siemens 808 control offers an ideal introduction to CNC applications with its simple, intuitive operator guidance. With the ISO 20 spindle taper, automatic tool clamping and a 4-way pick-up tool changer, the LabCenter enables practice-oriented training.

- Cast-iron machine frame

- Preloaded ball screws on all axes

- Spindle speeds up to 5000 rpm

- 4-station tool changer

- Mobile base with storage space

- Highlights

- Compact, mobile and professional for laboratories and training

- Electronic hand-wheel for efficient and professional set-up

- Mobile base with storage room for tools and materials

- Precisely machined frame made of high-quality cast iron

- Dovetail guides and preloaded ball screws with servo drives on all axes

- Max. spindle speeds up to 5000 rpm

- Spindle mount ISO 20

- 4-station tool changer ensures flexibility and optimum productivity

Control

Siemens 808D Advance control

- SINUMERIK 808D ADVANCE -- the perfect solution for modern standard machines

- CNC and drive communicate via a high-speed bus to ensure efficient positioning control plus high precision and optimum cutting performance

- This is topped by a guaranteed superior price/performance ratio

- This globally leading CNC technology provides high performance and power for the control of standard lathes

- In combination with a new generation of spindle and axis drives, the SINUMERIK 808D ADVANCE with 8.4" LCD provides an innovative ready-to-use digital CNC solution for modern standard machines

Advantages - Digital solution provides higher precision:

- Increased overload capacity supports a faster acceleration and deceleration of machine tools

- Constant cutting speeds result in an increased surface quality of the workpiece

Increased ruggedness:

- During heavy machining operations, an automatic spindle torque adjustment will help protect machining tools and spindle systems.

- The SINAMICS features a wide voltage range to prevent machine shut-downs during poor voltage supply conditions. This will significantly reduce machine down-times.

Increased operator comfort:

- A fast Ethernet connection facilitates easy start-up and diagnostics of machine tools and simplifies NC program use

Technical Details

| WORKING AREA | |

|---|---|

| Table dimensions | 400 mm x 145 mm |

| Table load capacity | 20 kg |

| Number of T-slots | 3 positions |

| T-slots, width | 12 mm |

| T-slots, spacing | 40 mm |

| Spindle nose-to-table surface distance | 60 mm - 240 mm |

| Throat | 200 mm |

| TRAVELS | |

|---|---|

| Travel X-axis | 260 mm |

| Travel Y-axis | 152 mm |

| Travel Z-axis | 180 mm |

| HEADSTOCK | |

|---|---|

| Spindle speed | 80 1/min - 5000 1/min |

| Spindle mount | ISO 20 |

| RAPID FEED | |

|---|---|

| Rapid feed X-axis | 2000 mm/min |

| Rapid feed Y-axis | 2000 mm/min |

| Rapid feed Z-axis | 2000 mm/min |

| FEED | |

|---|---|

| Work feed | 500 mm/min |

| Work feed X-axis | 500 mm/min |

| Work feed Y-axis | 500 mm/min |

| Work feed Z-axis | 500 mm/min |

| Max. torque feed motor X-axis | 2,2 Nm |

| Max. torque feed motor Y-axis | 2,2 Nm |

| Max. torque feed motor Z-axis | 2,2 Nm |

| TOOLING | |

|---|---|

| Number of tool stations | 4 positions |

| Tool size Ø x L (max.) | 10 mm x 110 mm |

| Tool weight max. | 0,5 kg |

| Tool-change time tool/tool | 10 sec |

| ACCURACIES | |

|---|---|

| Positioning accuracy X-axis | ± 0,015 mm |

| Positioning accuracy Y-axis | ± 0,015 mm |

| Positioning accuracy Z-axis | ± 0,015 mm |

| Repeatability X-axis | ± 0,01 mm |

| Repeatability Y-axis | ± 0,01 mm |

| Repeatability Z-axis | ± 0,01 mm |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 1 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,4 m x 0,9 m x 1,8 m |

| Weight | 450 kg |

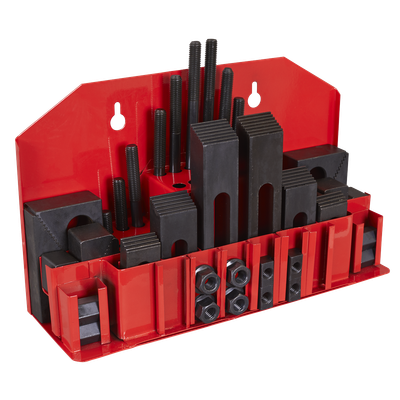

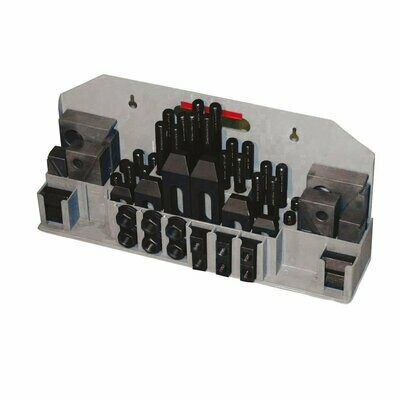

Standard Equipment

siemens 808D Advance control

electronic hand-wheel

4-station tool changer

mobile base

central lubrication

work lamp

operating tools

operating manual and programming instructions

Options

Wide range of tooling options available

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.