Knuth Servomill® KB 1500 Servo-Conventional Vertical Milling Machine sku 301300

Knuth Servomill® KB 1500 Servo-Conventional Vertical Milling Machine

(sku 301300)

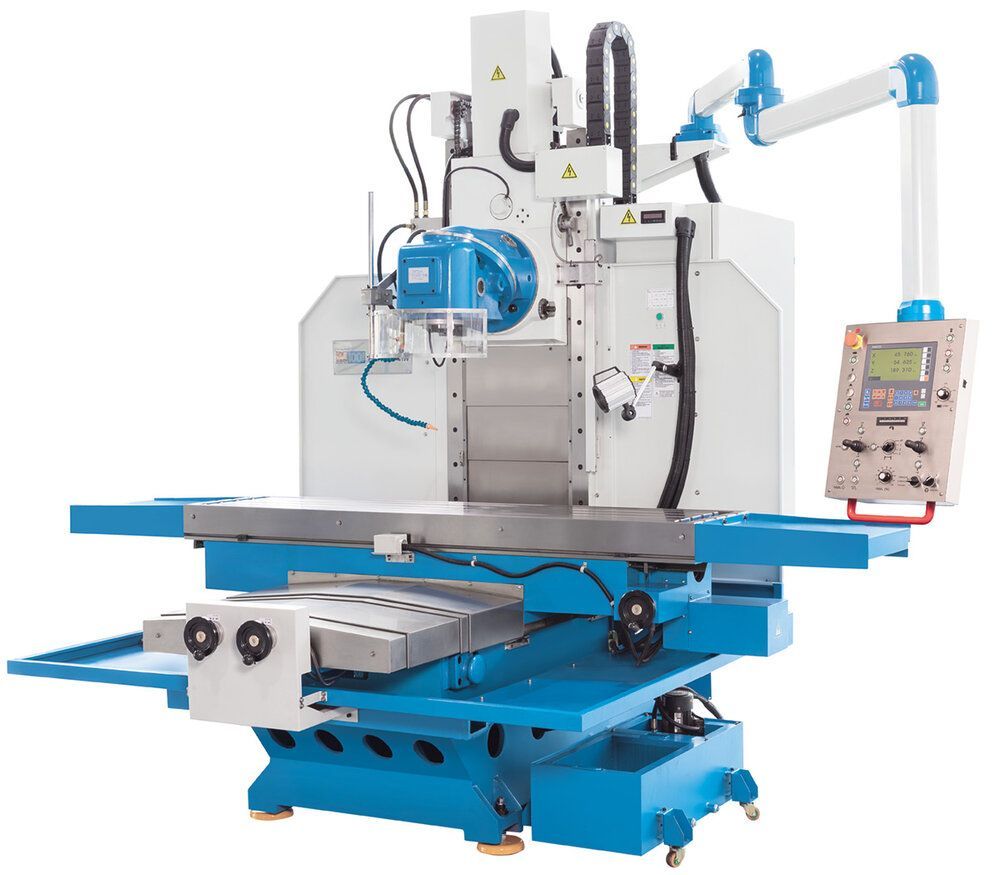

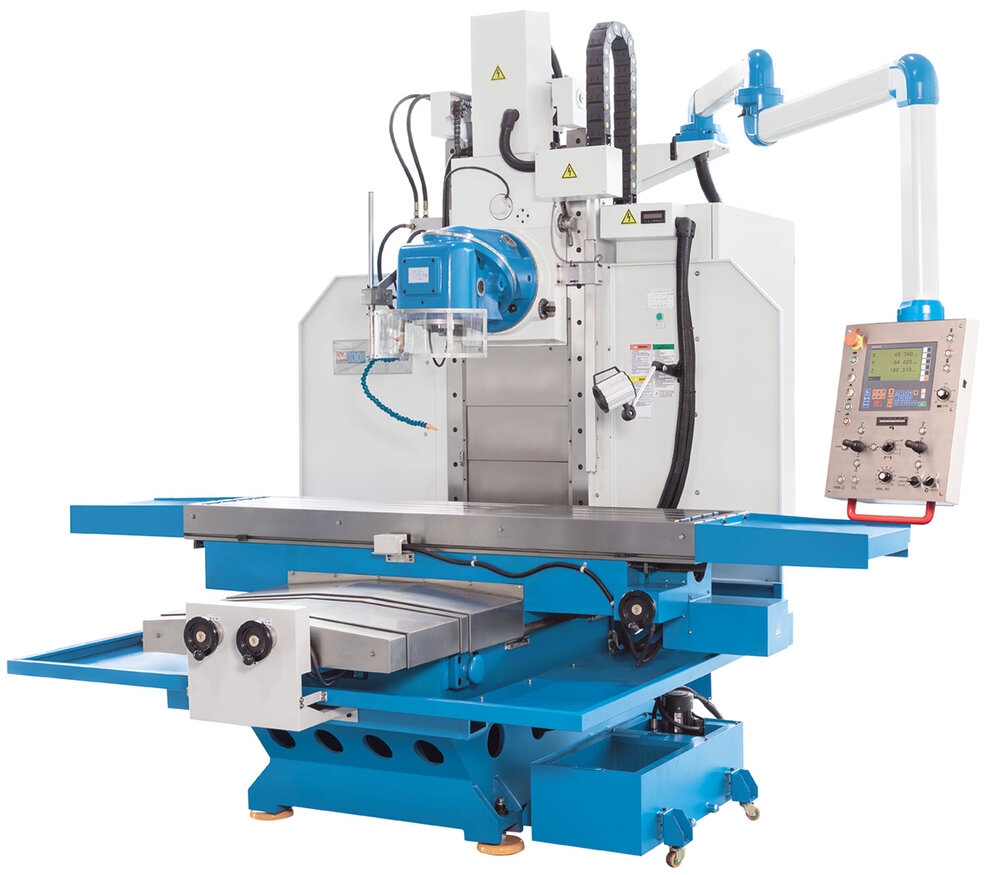

A bed-type milling machine with servo-conventional feed technology which combines a heavy-duty machine frame, wide guideways and high drive power for superior cutting performance.

Availability. Currently 4 weeks from receipt of order. Subject to no prior sales.

Highlights

Knuth Servomill® KB 1500 Servo-Conventional Vertical Milling Machine

The versatile Servomill® KB 1500 bed-type milling machine with servo-conventional feed technology combines a heavy-duty machine frame, wide guideways and high drive power for superior cutting performance. The universal milling head can be swivelled in two planes and positioned at almost any angle. Long milling arbors can also be used for horizontal machining. With electronic stops, electronic handwheels and additional milling functions, the Servomill® brings the benefits of CNC technology to large-scale production without the need for programming. The large work area and high maximum table load allow machining of large, complex workpieces. Together with the extensive range of accessories, this model is the ideal solution for plant and machine construction.

- Servo feed technology with electronic handwheels

- Ball screws in all axes

- 3 x 3 electronic stops

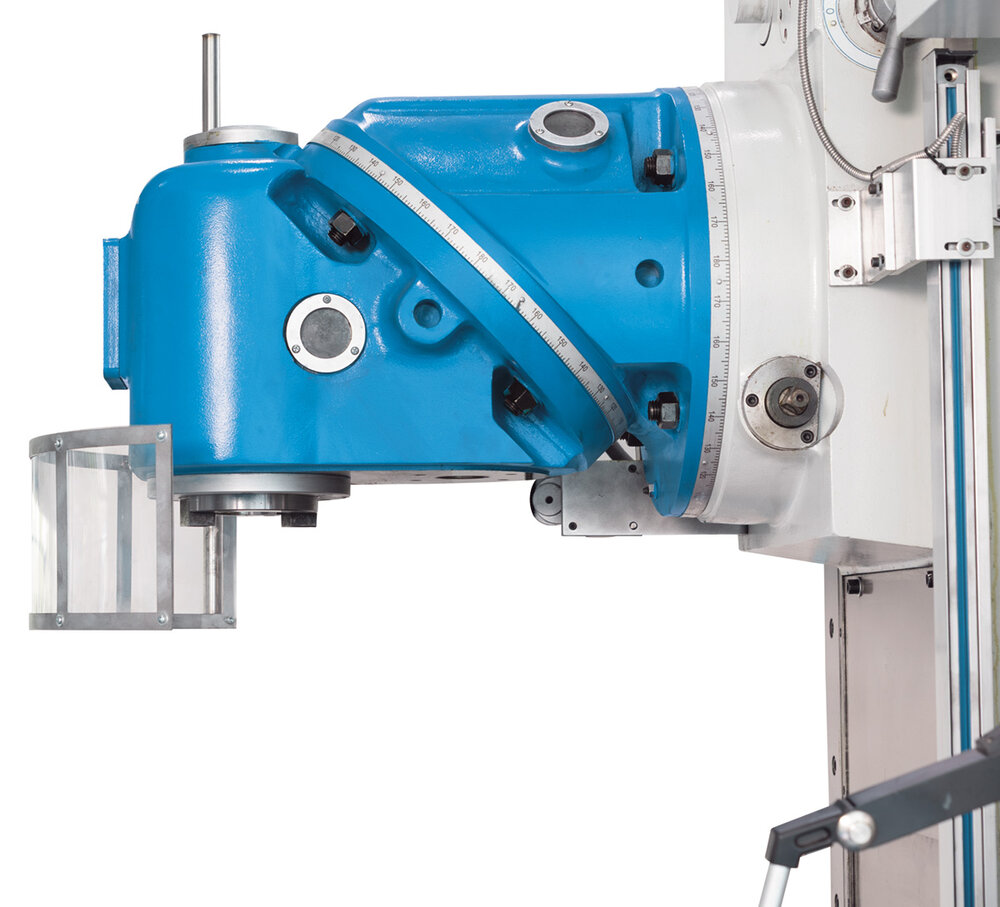

- Universal milling head with 2 swivel axes

- High maximum workpiece weight

- Infinitely variable spindle speed

Details

Highlights

- Integrated electronics allow for easier, more precise and more efficient conventional milling

- The Servomill machines represent a new generation of conventional milling machines

- All Servomill series are characterised by ease of operation, significantly increased precision and enhanced cutting performance

- The high reliability of all components used and their long service life significantly reduce maintenance costs and thus ensure increased availability

- The Servomill® KB 1500 is characterised by its solid machine bed, on which the large machining table moves in the X and Y axes

- The heavily ribbed fixed machine column, guides the compact universal milling head with drive unit in the Z axis

- The entire construction is characterised by its rigid and generous dimensions, high-quality casting and careful workmanship

- The very wide flat guides of the Y-axis guarantee stability under high table loads

- Die groß dimensionierte Schwalbenschwanzführung der X-Achse garantiert hohe Steifigkeit, Belastbarkeit und Kippsteifigkeit

- In addition, this design offers excellent damping properties and the option of finely adjustable wear compensation, making it particularly suitable for heavy-duty machining tasks with high stability requirements

- The large table travel and the large table clamping surface enable the machining of large individual workpieces or several workpieces in alternation

- The milling head unit runs on long flat guides and is additionally supported by a counterbalance

- A stable counter support is included in the scope of delivery for horizontal milling work with long milling arbours

- For high torques, the spindle speeds can be regulated in two gear stages via an inverter

- The universal milling head is characterised in particular by its stability and smooth running

- The angle adjustment is infinitely variable manually in the 90° and 45° planes

- This enables precise adjustment of the main spindle in freely definable spatial angles and simple swivelling into the horizontal

- The counter-holder guide is mounted for the use of long milling arbors, enabling high removal rates or simultaneous machining with several tools

- Powerful servomotors enable infinitely variable feed speeds and rapid traverse in all axes

- Preloaded recirculating ball screws in all axes guarantee precise, smooth and low-wear positioning without backlash and a long service life

- In the Z-axis, weight compensation ensures smooth traverse

- The machines are equipped with a comprehensive range of accessories as standard, such as LED work lighting and an extensive tool set with milling arbours and collets

- The coolant system is integrated in a large, separate and mobile tank and is easy to maintain

- The control panel is mounted on a long boom and can always be optimally positioned by the operator

- The centralised lubrication system reliably supplies all lubrication points with lubricant, making daily maintenance easier

- Electronics developed and built in Germany

- Positioning control for traveling pre-selected paths on all axes

- Zero backlash preloaded ball screws

- Servo-motors on all axes, infinitely variable feed, rapid feed, and speed control

- Electronic spindle load indicator

- Electronic hand-wheels on all axes

- X, Y and Z axis movement via joystick technology

- Integrated position indicator with precision glass scale

- Feed can be synchronized with the spindle speed

- Powerful servo motors allow infinitely variable feed speeds and rapid feeds on all axes

- The new generation of displays is more powerful, robust, and reliable

- For additional information, see manuals included with the standard equipment

- Easy to use: intuitive operation - practical layout of control elements and streamlined function

- Automatic feed on all axes and infinitely variable rapid feed with speeds up to 5000 mm/min

- Set limit stops on any axis with the push of a button - 3 stop positions per axis can be stored

- More precise: operated via electronic hand-wheels - axes are powered by high-quality servo drives that translate your hand movements with the precision and dynamics of modern CNC machines

- More reliable: drives, spindles, and measuring systems are totally enclosed or mounted in protective enclosures and virtually maintenance-free

- More capacity: this machine only uses premium drive components that are designed for continuous operation

- Maintenance-free: no regular maintenance needed for the entire feed drive

- The axes are moved by high-quality servo drives that implement your handwheel movements with the precision and dynamics of modern CNC machines

- Reliable, maintenance-free high-volume technology

- High rapid traverse speed reduces non-productive times

- Considerably less errors due to loseness (backlash), resulting in significantly higher precision

- Significantly reduced friction, no stick-slip effect, reduced heat buildup, minimal wear

- Micro-control via electronic hand-wheels offering the same handling and postioning as with a conventional machine, just smoother and more precise

- Maximum operator comfort for axis movements

- Easy handling during sequential processing

- Set 2 limit stops at 3 positions on each axis by the push of a button - these buttons are grouped around the feed switch for intuitive control

- This ensures high repeatability during coordinate drilling or pocket cutting, and siginificantly more positions can be set up than on conventional machines

- Assists the operator in the most efficient utilization of machine and tool capacities

- Reliable indicator helps avoid damages caused by overloads

Technical Details

| Working area | |

|---|---|

| Table dimensions | 2100 mm x 500 mm |

| Table load capacity (max.) | 1500 kg |

| Number of T-slots | 4 positions |

| T-slot (width x spacing) | 18 mm x 100 mm |

| Travels | |

|---|---|

| Travel X-axis | 1500 mm |

| Travel Y-axis | 650 mm |

| Travel Z-axis | 650 mm |

| Headstock | |

|---|---|

| Speed range, low | 6 1/min - 300 1/min |

| Speed range, high | 300 1/min - 1500 1/min |

| Spindle mount | SK 50 |

| Swivel angle | 360 deg |

| Spindle middle-to-table distance | 8 mm - 660 mm |

| Spindle center-to-column distance | 610 mm - 610 mm |

| Rapid feed | |

|---|---|

| Rapid feed X-axis | 6000 mm/min |

| Rapid feed Y-axis | 6000 mm/min |

| Rapid feed Z-axis | 3000 mm/min |

| Handwheel division X/Z/Y axis | 0,01 mm |

| Feed | |

|---|---|

| Feed speed X-axis | 3000 mm/min |

| Feed speed Y-axis | 3000 mm/min |

| Feed speed Z-axis | 2500 mm/min |

| Drive capacity | |

|---|---|

| Motor rating main drive | 15 kW |

| Motor rating coolant pump | 0,13 kW |

| Feed X-axis | 18 Nm |

| Feed Y-axis | 18 Nm |

| Feed Z-axis | 23 Nm |

| Motor rating X-axis | 3,6 kW |

| Motor rating Z-axis | 3,6 kW |

| Motor rating Y-axis | 4,6 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 3,22 m x 2,42 m x 2,8 m |

| Weight | 7000 kg |

Standard Equipment

Optional Accessories

Explore the range of compatible accessories in stock

Milling Chuck WELDON ISO 50 / Ø 6 mm

Milling Chuck WELDON ISO 50 / Ø 8 mm

Milling Chuck WELDON ISO 50 / Ø 10 mm

Milling Chuck WELDON ISO 50 / Ø 12 mm

Milling Chuck WELDON ISO 50 / Ø 16 mm

Milling Chuck WELDON ISO 50 / Ø 20 mm

Milling Chuck WELDON ISO 50 / Ø 32 mm

Intermediate sleeve, ST50 / ST40 DIN 2080

Intermediate sleeve, ST50 / ST30 DIN 2080

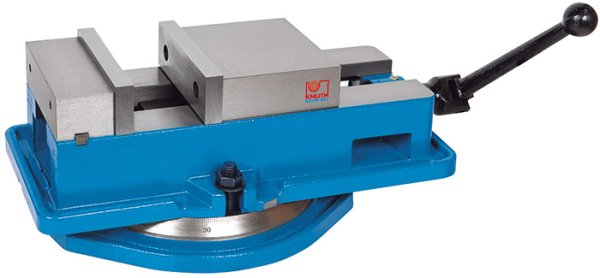

Machine vise with pull-down system NZM 200

MS 200 machine vise

HNCS 200V hydraulic machine vise

HS 200 Hydraulic machine vise

Rotary Table RT 320

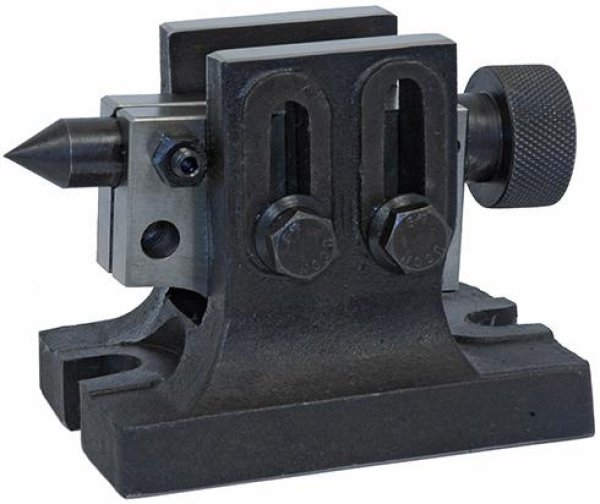

Tailstock / RT 320

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.