Knuth Guillotine Shear KMT M 2003 ( sku 133622 )

Knuth Guillotine Shear KMT M 2003 ( sku 133622 )

Ex Stock Availability, 1 - 2 Weeks to site typical.

Highlights

The KMT M series features a solid construction and is of high quality. These modern plate shears are equipped with a powerful drive motor, and a straight cutter angle ensures minimum workpiece torsion during cutting. The high-precision back gauge is positioned manually.

- Solid steel weldment with sliding block guide

- Cutters for stainless steel cutting are included

- Reversible cutters with multiple cutting surfaces

- Manual back gauge with travel display

- Work area secured by light curtain

Details

Machine Body and Drive System

- The machine frame is made of a very rigid, solid steel weldment and the cutter bar is sliding-block guided

- The high-precision guide ensures clean cuts and special cutters for machining stainless steel plates are included

- The upper cutters are reversible for use of both sides, and the lower cutters feature 4 cutting edges

- A rigid, continuous hold-down fixes the sheet metal plate right in front of the cut line

Material Support

- The rigid side angle stop simplifies alignment of the plate to the cut line

- Rugged support arms ensure a strong hold of large plates

- A wide support table simplifies workpiece handling

Ergonomic Design

- The bright LED illumination of the cut line creates a clearly visible shadow on the marked line

- Additionally, the smart machine enclosure design allows vertical view from the top for exact workpiece alignment

- An integrated cut counter keeps the user up to date

- All lubrication points and adjustment screws are easily accessible to simplify regular maintenance

Rear stop:

- The back gauge is positioned manually via a hand wheel

- An analog linear scale makes exact positioning easy and reduces down-times

- The easy accessible work area at the back gauge is secured by light curtain

Equipment

- The mobile foot switch gives the operator added flexibility and both hands are free for handling the workpiece

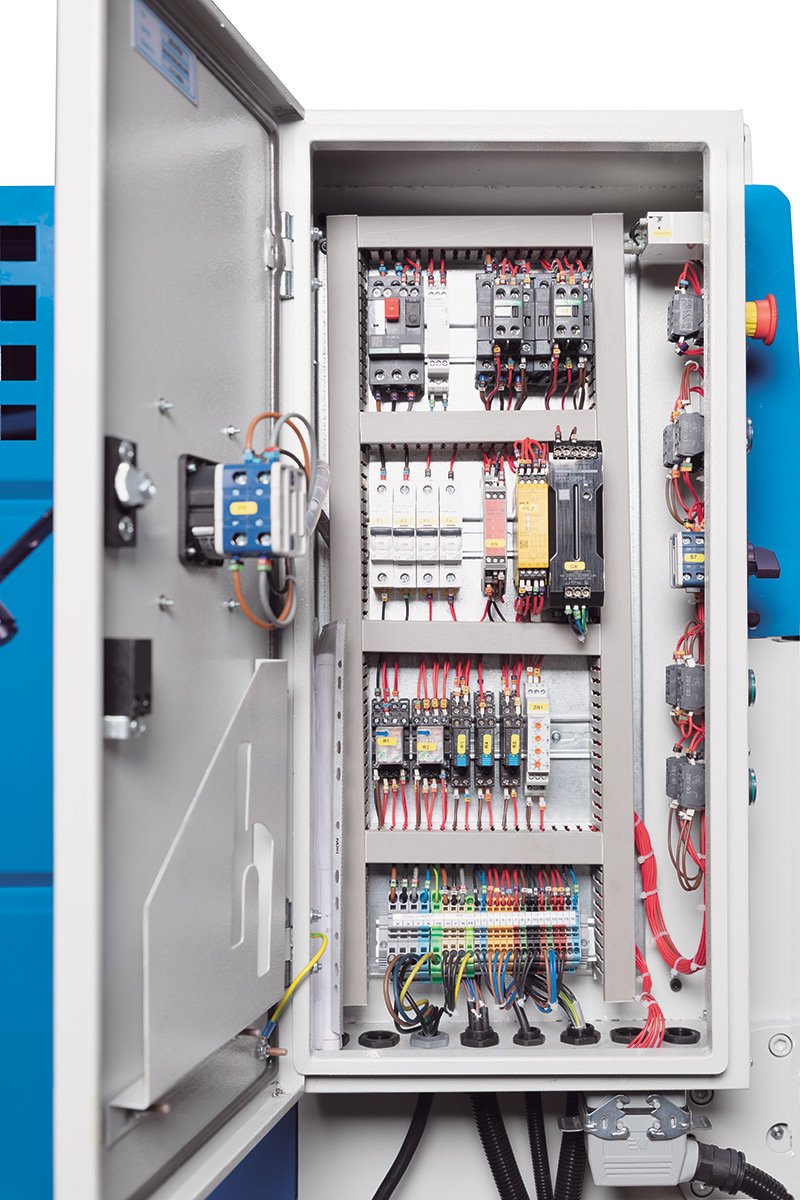

- High-quality electric components ensure reliable operation and maximum availability

- The full machine enclosure provides maximum safety, features a practical design and is precision machined

Technical Details

| Working area | |

|---|---|

| Working length | 2060 mm |

| Cutting angle | 1,3 deg |

| Work table height | 810 mm |

| Work table depth | 390 mm |

| Number of support arms | 2 positions |

| Support arms | 450 mm |

| Strokes per minute | 35 H/min |

| Back Gauge | |

|---|---|

| Rear stop | 750 mm |

| Cutting Capacities | |

|---|---|

| Plate thickness (min.) - 450 N/mm² | 0,25 mm |

| Plate thickness (max.) - 450 N/mm² | 3 mm |

| Plate thickness(max.) - 700 N/mm² | 1,5 mm |

| Drive capacity | |

|---|---|

| Motor rating main drive | 4 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 2,65 m x 2,1 m x 1,26 m |

| Weight | 1750 kg |

Standard Equipment

Optional Equipment

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.