Welcome to the Traxx Online E Store

With the Traxx Online E Store facility we enable our clients to buy our store products online using a credit or debit card by adding the product to your shopping basket and going to checkout. Follow the checkout process to complete your purchase. We accept leading cards including, Visa and Mastercard. Provide your email no. and telephone details to assist the shippers.

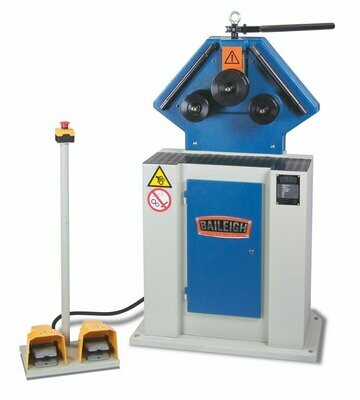

If you prefer to make your purchase payment via online banking by bacs/chaps transfer payment , contact us to assist you. We now also undertake hire purchase of the bigger machine tools in the store. Contact us for details.

Shipping: We only ship to accessible UK mainland sites with Traxx Online E Store. Clients wanting Overseas, Ireland, Remote Sites, Highlands / Islands delivery should contact us directly for further details and then we can assist you with this.

Phone or email for assistance 0796 3851 455

|

mroberts892@btinternet.com or ideally by messaging using the contact window.

Traxx Industries Limited registration number: 7321018 VAT registration number: 995435275

Address: 4 Langham Way, Hanchett Grange, Haverhill, Suffolk, CB9 7FJ, United Kingdom