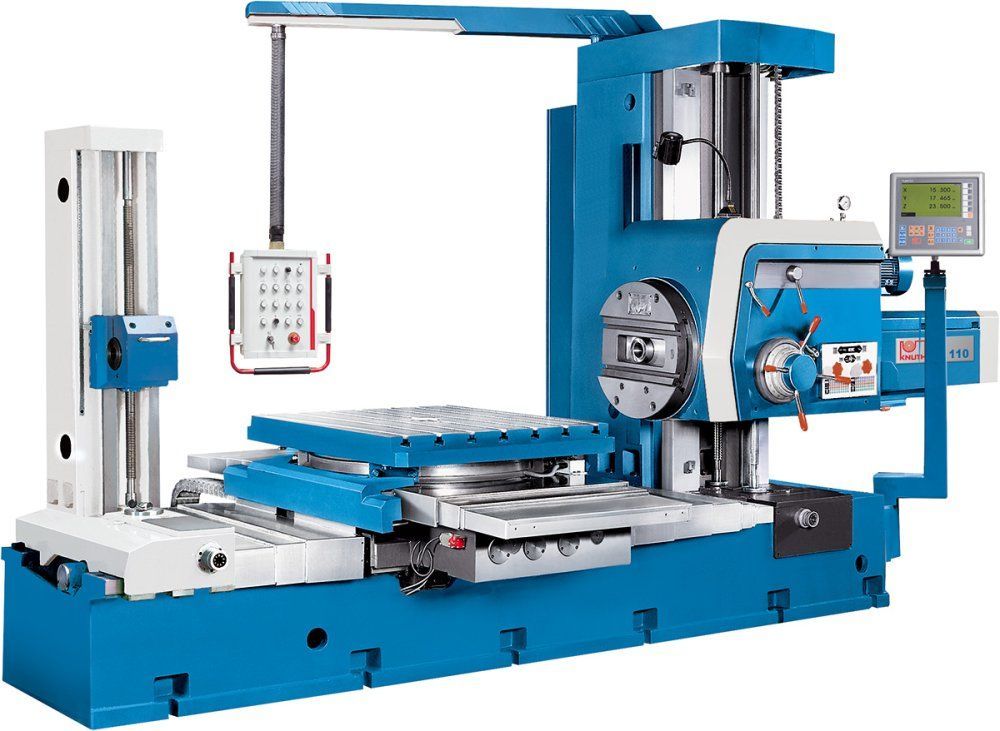

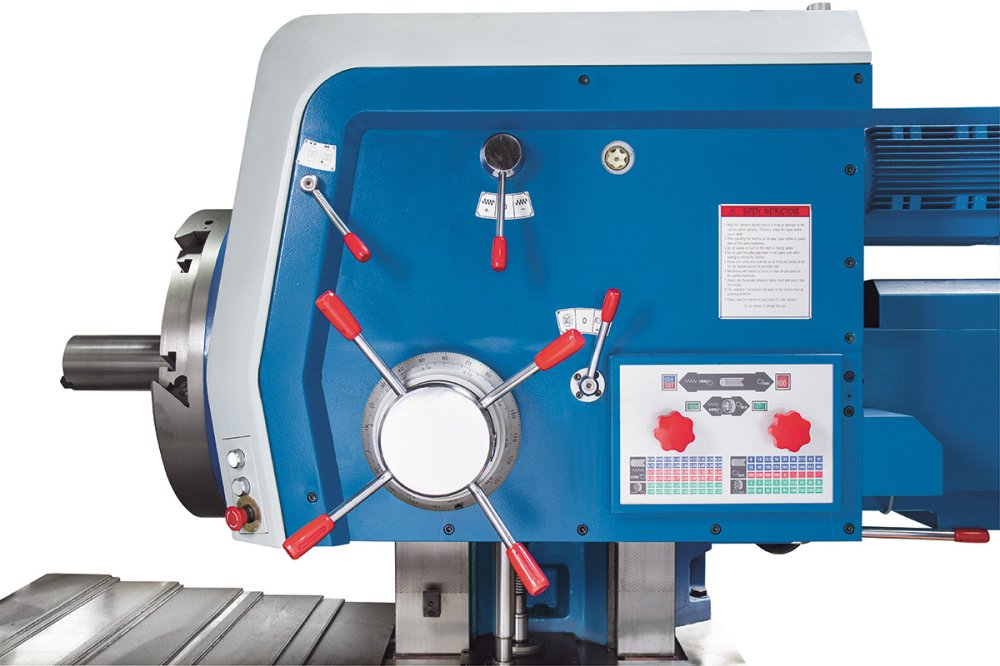

Knuth BO110 Conventional Milling and Boring Machine SKU : 301499

Knuth BO110 Conventional Milling and Boring Machine SKU : 301499

Made to order / 7 months lead time to site

Highlights

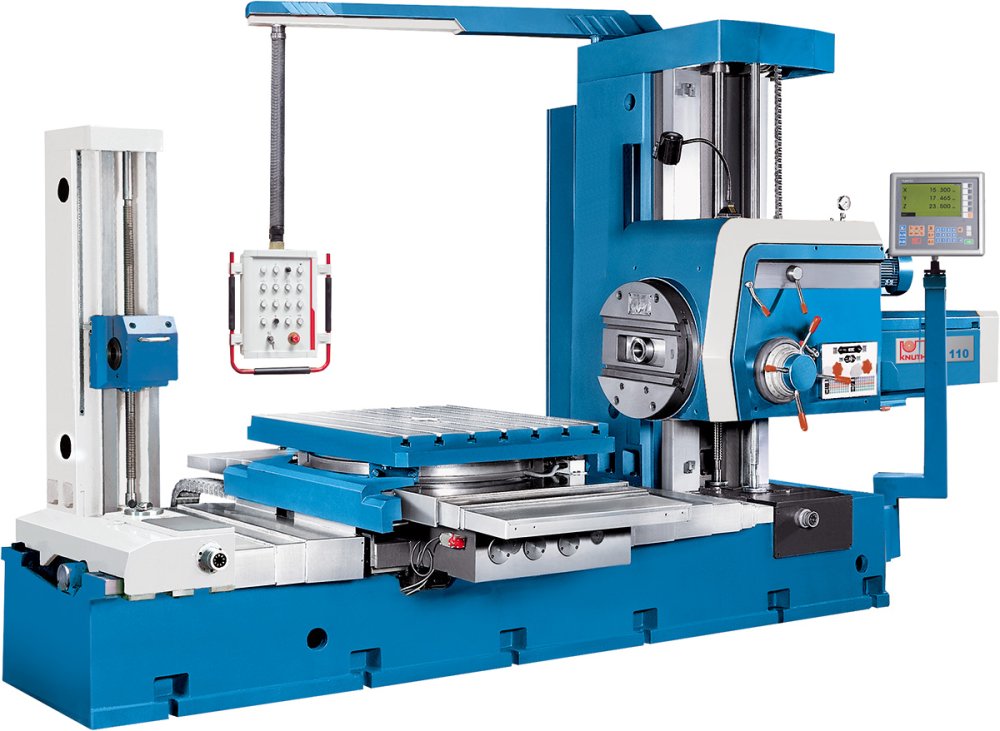

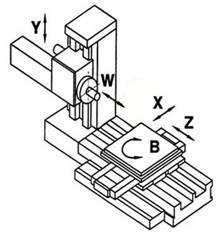

The BO series of conventional boring-milling machines is designed for horizontal, multi-sided drilling and milling of workpiece weights of up to 2.5 tons. The stand is fixed, while the table can move and rotate 360°. The drill head moves on the column and the spindle has a long stroke on the W-axis. Conventional boring mills also have a facing slide with a long stroke, which extends the application to include boring. High drive power and automatic feeds on all axes with rapid traverse enable efficient machining and short non-productive times.

- Large work area with W-axis and facing slide

- Thread cutting unit

- Rotatable clamping table with sighting device for 4 positions

- Telescoping stainless steel covers on all guides

Product Detail

- Rigid, hardened and precision-ground square guides ensure many years of accurate operation

- Mechanical functions that cannot be run simultaneously are provided with interlocks

- Headstock and feed gears are equipped with an overload clutch

- Lever-operated shift gears for positioning of the wheels in the desired position

- Faceplate and drill spindle with different task-specific speed ranges according to the various functions

- An optical sighting device enables fast positioning with maximum precision at 90°, 180°, 270° and 360°

- Telescoping steel cover protects the guides from chips and dirt

- BO 110 incl. tailstock (optional on BO 130)

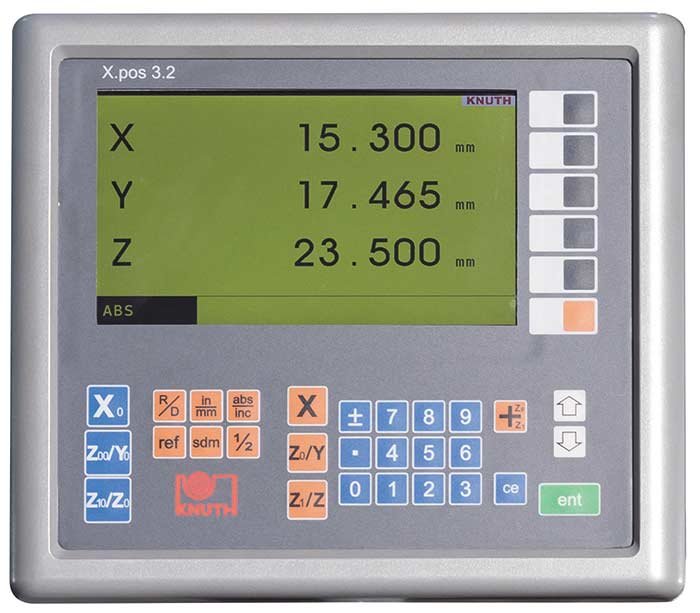

- More accuracy

- Lower error rate

- Increased productivity

- Resulting in valuable time savings

- For increased productivity

- Easy to read display

- Operator-specific features

- Convenient keyboard layout

- Resolution: 0.01/ 0.005 mm

- Default coordinates

- Axis position is maintained when display is turned off

- Hole circle pattern calculation

- Calculator function

- Storage for 10 tools

- Radius / diameter toggle

- Mm/inch conversion

- Easy expansion and maintenance-free operation

3-axis position indicator

Technical Detail

| Working area | |

|---|---|

| Drilling capacity | 50 mm |

| Table set up area | 1100 mm x 960 mm |

| Table load capacity | 2500 kg |

| Table rotation range | 4 x 90° |

| Spindle axis-to-table surface distance | 0 mm - 900 mm |

| Rotation speed of rotary table | 1 1/min |

| Travels | |

|---|---|

| Travel X-axis | 900 mm |

| Travel Y-axis | 900 mm |

| Travel Z-axis | 900 mm |

| Travel W-axis | 600 mm |

| Facing slide travel | 180 mm |

| Headstock | |

|---|---|

| Speed range | 8 1/min - 1000 1/min |

| Spindle diameter | 110 mm |

| Spindle torque (max.) | 1225 Nm |

| Spindle mount | SK 50 |

| Facing slide speed | 4 1/min - 200 1/min |

| Feed force, axial (max.) | 12,25 kN |

| Facing slide torque (max.) | 1960 Nm |

| Rapid feed | |

|---|---|

| Rapid feed X-axis | 2500 mm/min |

| Rapid feed Y-axis | 2500 mm/min |

| Rapid feed W-axis | 2500 mm/min |

| Feed | |

|---|---|

| Feed X-axis | 0,01 mm/R - 6 mm/R |

| Feed Y-axis | 0,01 mm/R - 6 mm/R |

| Feed Z-axis | 0,01 mm/R - 6 mm/R |

| Feed W-axis | 0,01 mm/R - 6 mm/R |

| Facing slide feed | 0,08 mm/min - 12 mm/min |

| Accuracies | |

|---|---|

| Read-out accuracy (optic) | 0,01 mm |

| Counter-bore accuracy | H7 Ra-1,6 µm |

| Drive capacity | |

|---|---|

| Motor rating main drive | 7,5 kW |

| Motor rating hydraulic pump | 0,37 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 4,88 m x 2,45 m x 2,75 m |

| Weight | 11500 kg |

Standard Equipment

Optional Equipment

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

can be quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Indicative price for a typical Sheffield postcode provided only.

Alternative shipping locations should indicate drop postcode and national location.

Comprehensive Installation / Commissioning / On Site Training Package

Fully inclusive rates can be arranged/ subject subject to a comprehensive assessment consultation/ meeting to discuss client needs.

Annual Service Contract

Fully inclusive rates can be arranged/ subject subject to a comprehensive assessment consultation/ meeting to discuss client needs.

Finance Availability

Looking to finance your equipment?

We have access to a variety

of funding sources

who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.